Introduction

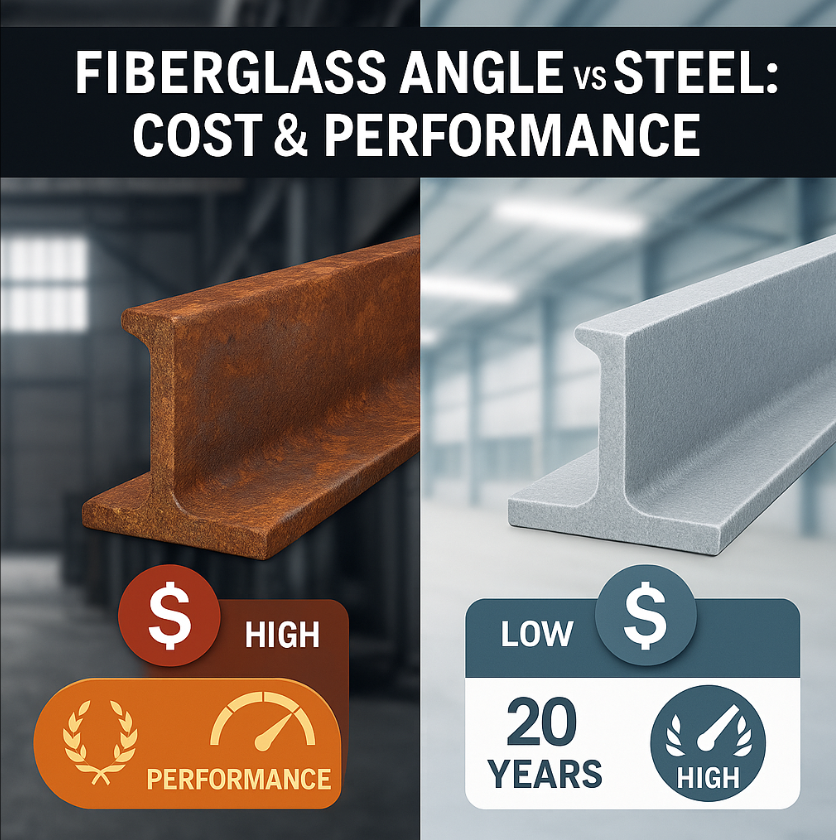

Rising labor costs, tighter sustainability targets, and harsher operating environments are pushing engineers to rethink the default choice of steel for L-shaped structural members. Fiberglass angle shapes, manufactured through the pultrusion process, now offer a corrosion-proof, electrically non-conductive alternative that can cut lifecycle spend in half without sacrificing strength. Unicomposite—an ISO-certified pultruder with a dedicated factory for standard and custom FRP profiles—has supplied millions of linear feet of composite angles to power utilities, chemical plants, and municipal infrastructure, proving that advanced composites have moved from “experimental” to everyday workhorse.

fiberglass angle shapes

Fundamentals of Angle Profiles in Structural Design

What Are Angle Shapes? Geometries & Key Load Paths

Angle profiles—commonly equal-leg (L × L) or unequal-leg (L₁ × L₂)—resist compression, tension, and torsion at right-angle joints, bracing frames, and supporting grating. Load travels along the inside corner (the “heel”), so stiffness and modulus drive performance more than pure tensile strength.

Material Properties Snapshot: Steel vs. Fiberglass Reinforced Plastic

| Property | Galvanized Steel Angle | Pultruded FRP Angle* |

|---|---|---|

| Density | 7.85 g/cm³ | 1.9 g/cm³ |

| Modulus of Elasticity | 200 GPa | 23 GPa |

| Tensile Strength | 370 MPa | 240 MPa |

| Thermal Conductivity | 54 W/m·K | 0.3 W/m·K |

| Corrosion Resistance | Requires coating | Inherent, ISO 175 tested |

*Typical E-glass/polyester matrix

Although steel is stiffer, fiberglass angle shapes deliver comparable ultimate strength at ~75 % weight reduction, unlocking lighter foundations and faster installs.

Cost Comparison Across the Lifecycle

Up-Front Material & Fabrication Costs

A 50 mm × 50 mm × 6 mm steel angle averages US $1.30 per meter (material only). The equivalent fiberglass profile lists at US $2.10 per meter. Fabrication favors FRP: cutting with diamond blades needs no post-cut galvanizing, whereas steel often demands plasma cutting, drilling, and weld prep, adding 20 % to installed cost.

Maintenance, Corrosion, and Replacement Expenses

Corrosion is the silent budget killer. Coastal and wastewater sites typically re-paint or re-galvanize steel angles every 3-5 years at ~US $4.00/meter per cycle. FRP requires only visual inspection; salts and H₂S do not attack the glass/resin matrix. Over a 20-year service window, maintenance savings alone offset the higher purchase price.

Real-World ROI: 10-Year Wastewater Plant Case Study

Anonymized municipal records show that switching 1,400 m of walkway bracing from steel to fiberglass angle shapes saved US $68,000 in recoating labor and halted three shutdowns for corrosion repair. Payback occurred in year 4; total cost of ownership was 55 % lower than the steel baseline.

Performance in Aggressive or Specialized Environments

Chemical & Moisture Resistance Metrics

Pultruded FRP angles tested per ASTM D543 retained >95 % tensile strength after 3,000 h immersion in 20 % sodium chloride. Steel lost 15 % cross-section to pitting in the same test unless epoxy-coated. In acid scrubbers or fertilizer plants, the gap widens further.

Weight-to-Strength Ratio & Installation Efficiency

Composite crews routinely carry 6 m lengths by hand—no crane time, no hot work permits. On an elevated conveyor retrofit in Texas, installers documented a 35 % reduction in man-hours versus steel because they could lift, align, and bolt FRP angles without rigging delays.

Safety & Dielectric Advantages Near Live Electrical Equipment

“FRP gives us a built-in insulating barrier, so we no longer need fiberglass ladders or extra arc-flash clearances,” notes a senior substation engineer at a Mid-Atlantic utility. With a dielectric strength of ≥ 25 kV/mm, fiberglass angle shapes eliminate stray current paths that can cause galvanic damage—or worse, electrical accidents.

Design & Specification Best Practices

Selecting Profile Dimensions, Resin Systems, and Fillers

For indoor dry service, an economy polyester resin often suffices. Outdoor UV or chemical splash zones should specify vinyl ester. Additives like alumina trihydrate raise flame spread ratings to meet ASTM E84 Class A. Unicomposite maintains standard mold sizes from 25 mm up to 150 mm legs; custom leg thickness or radii are pultruded with lead times of 2-4 weeks.

Engineering Standards, Load Tables, and Compliance Checks

Use ACI 440 and ASCE 440.1R guidelines when converting steel to FRP. Because modulus differs, designers should check deflection limits first, then ultimate strength. Unicomposite supplies FEA-backed load tables for simple span, cantilever, and braced-frame conditions, including safety factors of 2.5-3.0.

Partnering With an ISO-Certified Pultruder for Custom Solutions

Working with an ISO-9001 plant such as Unicomposite ensures batch-to-batch resin traceability, laser-verified geometry, and third-party tensile coupons kept on file. Their in-house machinists can combine angle shapes with square tubes or plates into turnkey kits, delivered pre-drilled and labeled for field bolt-up.

Conclusion

Steel still dominates where ultra-high stiffness or extreme heat is decisive, but in corrosive, electrically sensitive, or access-challenged sites fiberglass angle shapes consistently provide lower lifecycle cost, faster installation, and built-in safety benefits. Engineering or procurement teams ready to quantify the gains can request Unicomposite’s detailed load tables or a project-specific quote today.

Frequently Asked Questions

Q1. How long do fiberglass angle shapes last in outdoor service?

Laboratory aging and field data show service lives of 25–50 years with negligible strength loss, provided the correct UV-stabilized resin is chosen.

Q2. Can composite angles handle high temperatures?

Standard polyester pultrusions operate to 120 °C; switching to vinyl ester or phenolic resin lifts continuous service temperature to about 180 °C.

Q3. What are typical lead times for custom dimensions?

Once drawings are approved, Unicomposite’s tool-change system delivers most non-standard angles in 15–25 days, including QA testing.

Q4. Are there design codes for FRP structural members?

Yes. ACI 440, EN 13706, and ASCE 440 provide material factors, creep models, and allowable stress limits that engineers can reference.

Q5. How are FRP angles connected to steel or concrete?

Stainless bolts, adhesive-bonded studs, or FRP gusset plates are common. Holes are drilled with carbide bits on site—no galvanizing touch-up required.

info@unicomposite.com

info@unicomposite.com