The resin that is chosen also depends on many variables. Some of those variables are similar to the ones used when choosing a reinforcement- where you are applying it, what properties you need, why you will be using it and cost. It will also depend on the type of reinforcement you want to use, whether you will be finishing with a gel coat or not and whether you need it to be corrosion, abrasion or UV resistant.

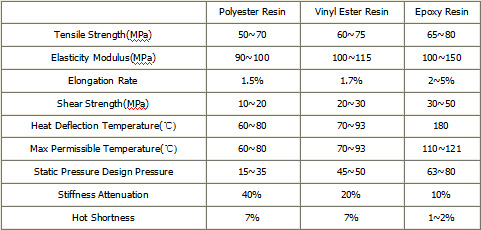

Unsaturated polyester resin: A kind of thermosetting resin, the mechanical strength of the polymer is very low, it cannot meet the most of use requirements. The price is not expensive. The core advantage of unsaturated polyester resin is that it can be cured at room temperature, the flexibility makes it suitable for large fiberglass products production at site.

Vinyl ester resin: A kind of thermosetting resin, and it has good performance on corrosion resistance, and it’s suitable for most of the anti-corrosion requirements. Disadvantages: mechanical performance is not good. Vinyl ester resin adhering to the excellent properties of epoxy resin, curing and forming is more excellent, can be dissolved in styrene and acrylic monomers,due to the advantages of both epoxy and unsaturated, its application fields are expanding.

Epoxy resin: A kind of important thermosetting resin, and it has high mechanical strength and good alkali resistance, but not resistant to corrosion. Epoxy resin has good electrical properties and adhesive force, but the brittleness and the performance of business flexibility, so the epoxy cover layer (or solder resist) materials consisting of a protective layer, via multiple bending occurs ‘cracking’, fault block, finally into patches and stripped down.

info@unicomposite.com

info@unicomposite.com