Fiberglass (Fiberglass Reinforced Plastic) rebar is made of high-strength glass fibers along with a highly durable resin. Developed as a superior alternative to steel in concrete reinforcement, FRP Rebar is used to reinforcing concrete in applications where concrete is exposed to water, salt water, or chemical environments.

Advantages:

■ Non-Corrosive – will not corrode exposed to a wide variety of corrosive elements including chloride ions.

■ High Strength-to-Weight Ratio – provides good reinforcement in weight-sensitive applications.

■ Non-Conductive – provides excellent electrical and thermal insulation.

■ Excellent Fatigue Resistance – performs very well in cyclic loading situations.

■ Good Impact Resistance – resists sudden and severe point loading.

■ Magnetic Transparency – not affected by electromagnetic fields; excellent for use in MRI and other types of electronic testing facilities.

■ Light Weight – easy to be transported, no need for lifting equipment, saving high machine and manual costs.

We supply below four kinds of fiberglass rebar

FRP rebar can be roughly divided into four categories according to the material and performance: FRP rebar wrapped in dry yarn, FRP rebar wrapped in wet yarn, FRP rebar with dents, High Load FRP rebar.

■FRP rebar wrapped in dry yarn–Enhance adhesion to concrete, excellent corrosion resistance, higher strength-to-weight and ratdurability.

■FRP rebar wrapped in wet yarn–Provide excellent moisture protection, more suitable for applications with moisture.

■FRP rebar wrapped with dents–High tensile strength, corrosion resistance and durability, surface indentation improves bond strength, stress transfer and adhesion of protective coatings.

■High load rebar–Durability, longevity, and higher structural performance, reducing corrosion-related maintenance costs.

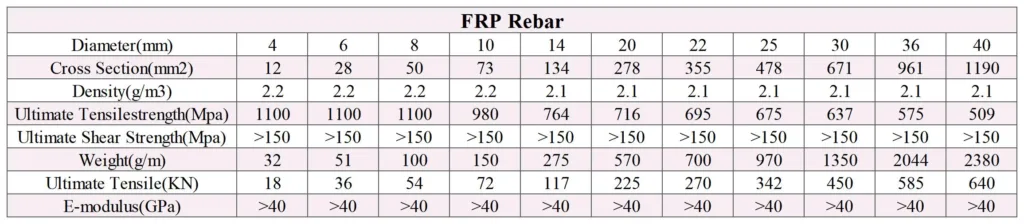

General Technical Data

We supply FRP rock bolt as well

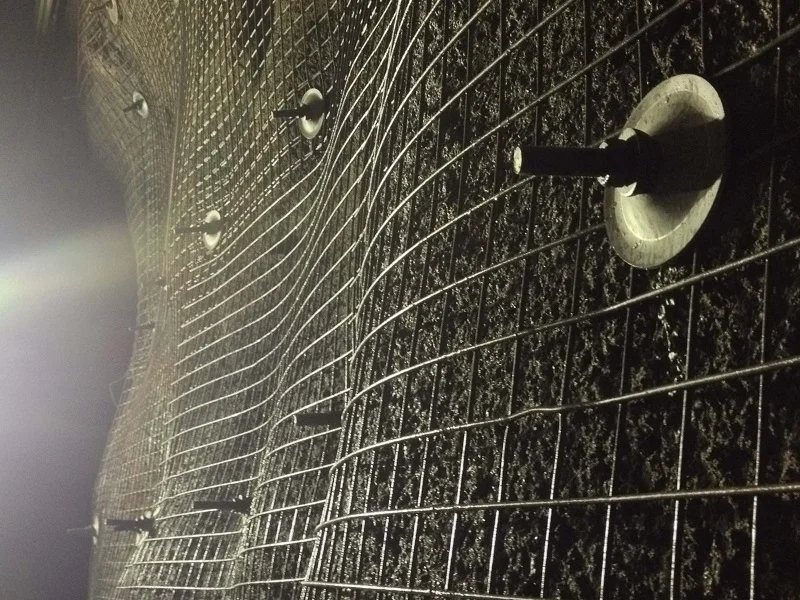

■Rock bolt rebar (support / joint system)

Rock bolts are commonly used in civil engineering and mining to reinforce and stabilize rock masses. They involve inserting a steel rod or bar into a drilled hole, which is then grouted in place using cement or resin. Rock bolts withstand tensile forces and evenly distribute load, increasing overall strength. Types include fully grouted, mechanically anchored, and friction rock bolts. They control rock movements, reduce deformation, and prevent collapses.

Available dimension: Typical diameter 16, 18, 20, 22, 24mm

Application: Rock reinforcing underground like mining, sub-way, etc

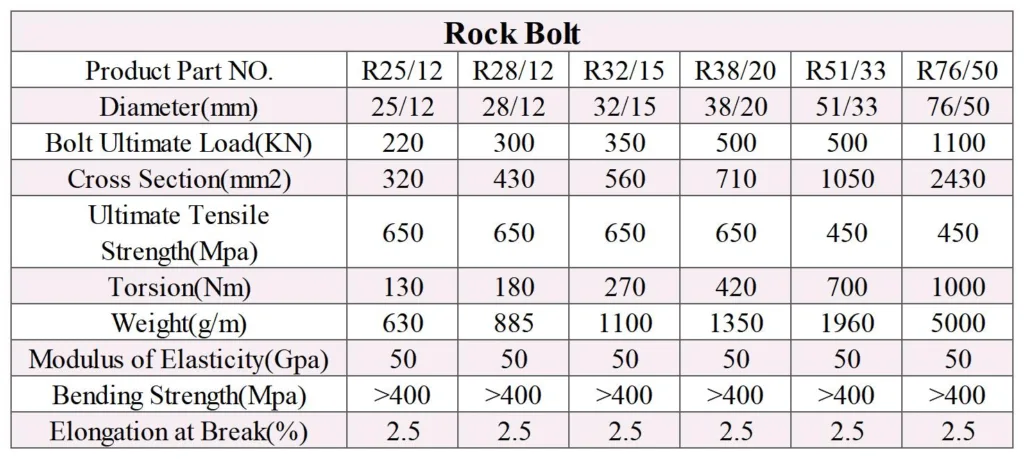

Technical data:

Our Commitment to Customer Satisfaction

1. Efficient Large-Scale Production: With advanced machinery and streamlined processes, our factory ensures prompt delivery of large-scale orders.

2. Tailored Solutions: We offer extensive customization options for diameter, length, and configuration to meet your project’s unique requirements.

3. Expert Technical Support: Our dedicated team provides comprehensive guidance and assistance throughout your project, from design to on-site training.

4. Stringent Quality Assurance: Adhering to international standards, we conduct rigorous testing to guarantee the highest quality FRP rebar.

Partner with us for Dependable Reinforcement Solutions

Experience excellence, innovation, and customer satisfaction with our FRP rebar factory. Contact us today to discuss your project requirements and partner with us for reliable reinforcement solutions.

info@unicomposite.com

info@unicomposite.com