Introduction

Snowplows, delivery vans, and 53-foot trailers all share one need when they roll onto your property: clear sightlines. Fiberglass driveway marker rods give facility managers a simple, low-cost way to keep traffic lanes, cul-de-sacs, and loading docks visible in every season. Because Unicomposite is an ISO-certified pultrusion manufacturer, its B2B customers—utilities, civil contractors, OEM builders—get rods engineered to tight tolerances and shipped in bulk without supply-chain guesswork.

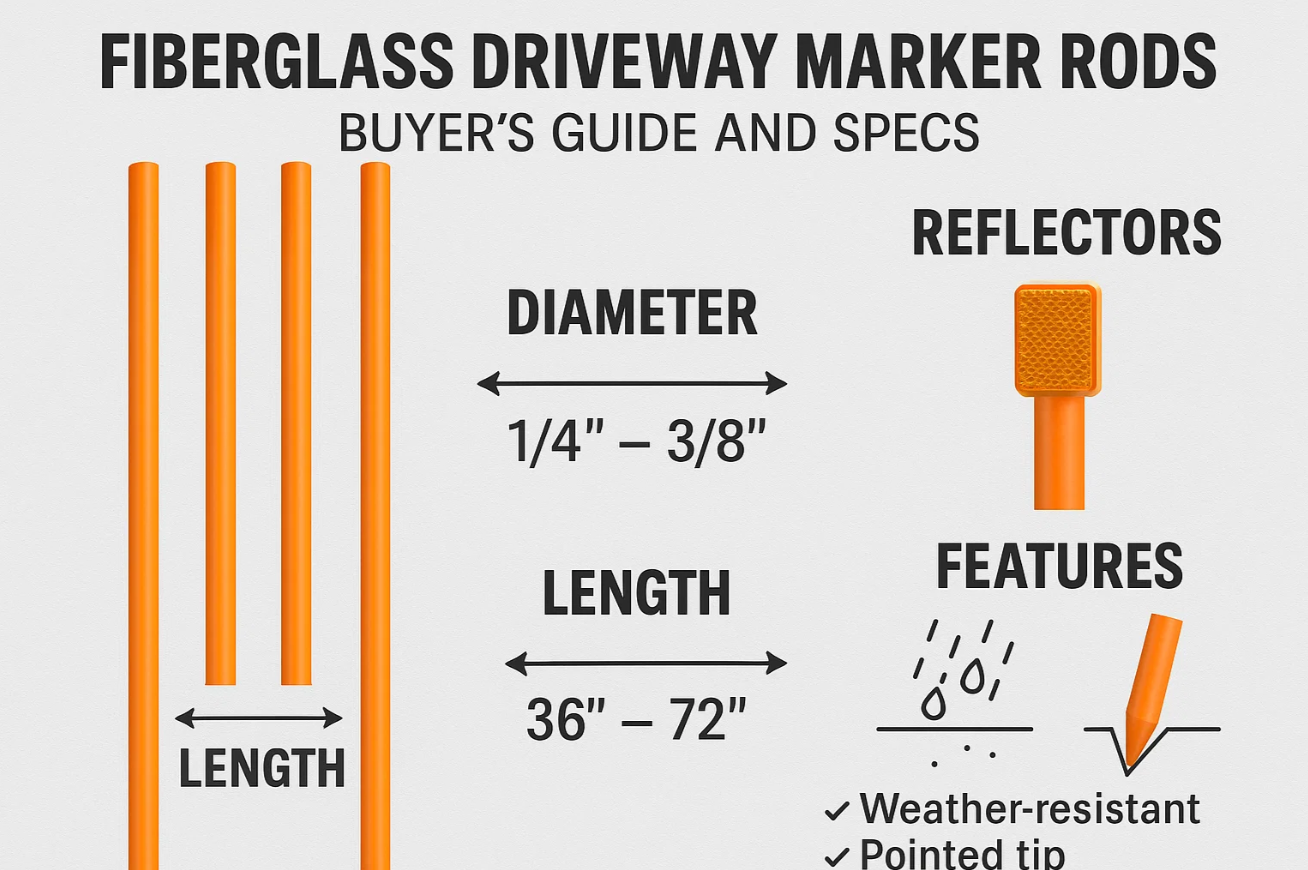

fiberglass driveway marker rods

Understanding the Material Advantage

Why Fiberglass Beats Metal & Plastic

Steel stakes bend; PVC fades and splinters in deep cold. Pultruded fiberglass blends E-glass and thermoset resin to deliver a tensile strength of >120 ksi while weighing 70 % less than steel. ASTM B117 salt-spray tests show fiberglass loses under 0.5 % mass after 1,000 hours, far outperforming galvanized rod benchmarks.

“We dial in the glass-to-resin ratio on every production run so the rods flex instead of kinking when they’re hit,” explains Zhang Wei, Unicomposite Senior Process Engineer.

Corrosion Resistance and Dielectric Safety

In substations and solar farms, stray currents can turn a metal post into a shock hazard. Fiberglass is non-conductive and naturally immune to rust, meeting IEC-61109 leakage tests without extra coatings—an often-overlooked benefit for utility buyers.

Choosing the Right Specifications for Your Project

Core Dimensions

Diameter: 3/8 ″ is the North-American fleet standard; 1/2 ″ gives extra stiffness for forklift traffic.

Length: 48 ″ keeps the reflective tip above a 12-inch snow pack; 60 ″ suits sound-barrier berms or tall landscaping beds.

Color: OSHA yellow or blaze orange remain the most visible against snow; lime green works well on asphalt yards.

Reflective Options

Retro-reflective sheeting in ASTM Type IV yields up to 800 cd/lux/m². Many municipalities specify a 4-inch band set 2 inches below the tip to align with DOT visibility codes.

Volume Purchasing Tips

Contractors ordering 5,000 pcs or more can request rods cut to odd lengths (e.g., 42 ¼ ″) at factory, eliminating on-site trimming and silica dust concerns.

Installation Best Practices for Longevity

Site Prep Across Substrates

Soil: Use a 3/8 ″ pilot rod to open the hole and avoid splitting turf.

Asphalt: A rotary hammer with 7/16 ″ masonry bit prevents micro-cracks in the pavement.

Concrete: Core drill 1/2 ″ holes 2 ″ deep, inject epoxy, and insert the rod while turning for full wetting.

Recommended Tools & Torque

A manual driver with a cup head spreads load and keeps the dome cap intact. Target 20 lb-ft insertion torque—enough grip without crushing the fiberglass shell.

Seasonal Maintenance Tips

Rinse off road salt each spring, and spin the rod 180° if abrasion marks appear; pultruded fibers run full-length, so performance remains unchanged.

Compliance & Safety Standards You Must Know

OSHA & DOT Visibility

Industrial yards lit below 5 fc must mark fixed obstacles with reflective devices visible at 1,000 ft. Fiberglass rods fitted with Type IV tape meet that distance on low-beam.

ANSI Color Codes

Use red at fire-lane borders, blue for hydrant clear zones, and green for recycling pad per ANSI Z535.

Record-Keeping

Log positions and inspection dates in a GIS or spreadsheet; Unicomposite customers often tag lots by GPS to schedule annual checks—an insurance auditor favorite.

Case Study: Cutting Snow-Plow Downtime by 40 %

Background

A Midwest county ran five Class 8 plows across 220 lane-miles of service yards. Steel rebar markers bent every storm, forcing crews to stop and replace stakes.

Deployment

Facilities installed 3/8 ″ × 60 ″ fiberglass driveway marker rods with 6-inch Type IV reflectors at 20 ft intervals.

Results

After two winters:

Broken markers per season dropped from 780 to 112 (–86 %).

Average plowing route finished 40 % faster.

ROI reached 6.5 months, including labor savings.

Cost of Ownership & ROI Calculator

Up-Front vs. Lifecycle

| Item | Steel Rebar | PVC Stake | Fiberglass Rod |

|---|---|---|---|

| Unit cost (bulk) | $1.10 | $0.85 | $1.45 |

| Avg. breakage/yr | 60 % | 40 % | 8 % |

| 5-yr total/1000 ft | $11,000 | $6,800 | $3,130 |

Failure Modes

Fiberglass typically fails only when run over by track loaders; UV or salt rarely degrade the matrix within a 5-year window.

Bundled Supply & Custom Fabrication

Ordering rods along with fiberglass snow-stake driveway signs or cable-tray supports can cut freight by 18 %—a frequent strategy among Unicomposite’s OEM partners.

Conclusion

Fiberglass driveway marker rods help industrial buyers hit three goals at once: longer service life, better safety compliance, and lower five-year spend. If you need tailored diameters, unique pigment matches, or just a fast LTL shipment, reach out to Unicomposite’s engineering desk for a no-obligation quote and sample kit.

Frequently Asked Questions

Q1. How long do fiberglass driveway marker rods last in extreme climates?

Field data shows an average service life of 5–7 years in freeze-thaw zones, provided they’re not struck directly by heavy equipment.

Q2. Can I get custom colors or stripes to match corporate branding?

Yes. Pigments are integrated into the resin during pultrusion, and Unicomposite can add multiple reflective bands or logo sleeves without compromising strength.

Q3. What’s the minimum order quantity for custom lengths?

Typical MOQ is 2,000 pcs for non-standard lengths; shorter trial runs may be available for an engineering qualification fee.

Q4. Are the rods recyclable?

Fiberglass recycling is limited, but rods can be ground for filler in concrete or asphalt. Some buyers repurpose retired rods as garden stakes.

Q5. How quickly can Unicomposite ship bulk orders to North America?

Standard lead time is 4 weeks ex-works plus ocean transit; air-freight is possible for urgent replacement orders under two pallets.

info@unicomposite.com

info@unicomposite.com