Introduction

Fiberglass reinforced plastic (FRP) wall and ceiling panels have become the go‑to cladding in food‑processing plants, commercial kitchens, laboratories, and water‑treatment facilities because they shrug off moisture, chemicals, and impact. Yet even durable panels can fail prematurely if they’re slapped up without a plan. This guide shows you how to install fiberglass reinforced plastic panels efficiently and code‑compliantly—using real‑world field experience, industry standards, and lessons learned from large‑scale retrofits. Unicomposite, an ISO‑certified pultrusion manufacturer with its own factory in China, contributes insights from thousands of square meters of bulk FRP projects worldwide, giving buyers an inside look at what works and what wastes money.

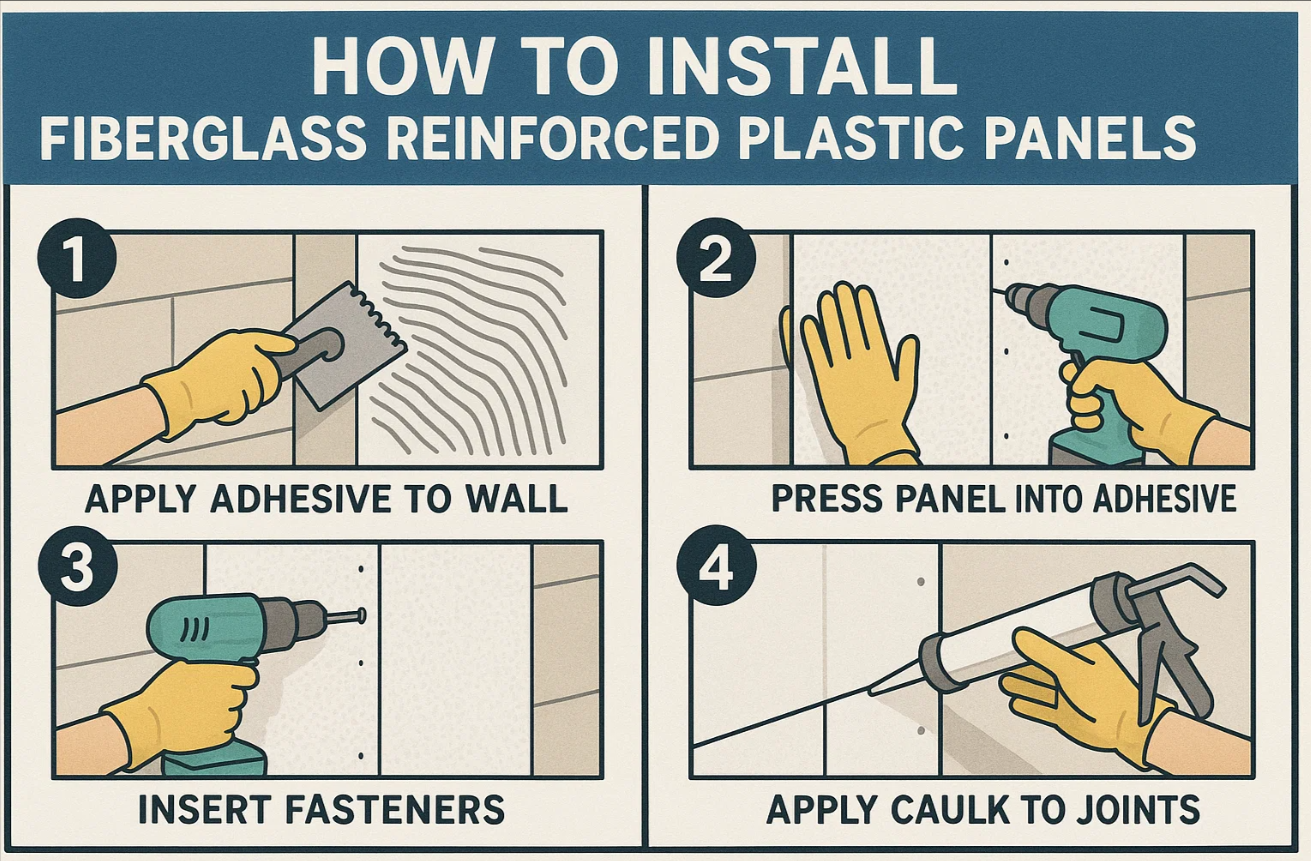

how to install fiberglass reinforced plastic panels

Assessing Project Requirements (Who & Why)

Identify Service Environment & Load Conditions

Every successful installation begins with understanding who and what the panels must protect. Are you lining wash‑down food zones, retrofitting a chlorine room, or building a chilled storage area? Each environment dictates different resin systems, surface textures, and reinforcement schedules.

Verify Building Codes, ASTM & OSHA Guidelines

Local building departments typically reference ASTM C840, C1338, and OSHA 1910 for cladding, fire spread, and worker safety. Confirm classifications—Class A flame‑spread vs. Class C—before ordering panels.

Choose Panel Thickness, Finish & Reinforcement

Thicknesses run from 1 mm liners to 6 mm structural sheets. In corrosive zones, Unicomposite recommends 2.3 mm gel‑coated FRP with marine‑grade resin and UV inhibitors, balancing strength and economy for multi‑shift facilities.

Gathering Tools, Materials & Safety Gear (How)

Essential Tools Checklist

Fine‑tooth carbide circular saw or track saw

Portable drill with countersink bits

75 mm serrated laminate roller

Caulk gun & notched trowel

Approved Adhesives, Fasteners & Trim Kits

Use a low‑VOC, moisture‑cure polyurethane adhesive rated for FRP (ASTM E84 compliant). Pair with stainless or nylon drive rivets every 400 mm on center. Color‑matched PVC or anodized‑aluminum trims speed finishing.

PPE & Site Safety Practices

According to the Center for Construction Research and Training, airborne dust from cutting composite panels can reduce lung capacity by up to 9 % over a decade without protection. Equip installers with P100 respirators, safety glasses, and cut‑resistant gloves.

Surface Preparation & Layout

Clean, Level & Dry Substrates

FRP only sticks as well as the surface beneath it. Remove flaking paint, grease, and high spots; concrete moisture should read ≤ 12 % on a pin meter.

Install Moisture Barriers & Allow for Thermal Expansion

In high‑humidity rooms, add a 6‑mil polyethylene vapor barrier and leave a 3 mm perimeter gap for movement.

Dry‑Fit Panels and Mark Reference Lines

Snap horizontal chalk lines at 1 m intervals. Veteran tip: mark stud centers on blue tape so fasteners bite solid framing, not empty gypsum.

Step‑by‑Step Installation Process

Cutting FRP Panels Cleanly — Expert Technique

Clamp sacrificial plywood beneath the sheet and push the blade slowly to avoid chipping. A handheld oscillating tool excels for outlet cut‑outs.

Applying Adhesive & Mechanical Fastening Sequence

Spread a 6 mm bead in a serpentine pattern, keeping 50 mm from edges.

Press the panel from center outward with a serrated roller, expelling air pockets.

Seat rivets or screws within 20 minutes while adhesive is still tacky.

Sealing Joints, Edges & Penetrations

Fill gaps with 100 % silicone RTV; tool smooth for a sanitary, water‑shedding joint. Around pipes, embed a backer rod first to maintain a flexible buffer.

Seven Pro Tips for a Professional Finish

Acclimate panels on site for 24 hours at operating temperature (± 5 °C) to prevent bowing.

Roll seams twice—first perpendicular, then parallel to trim caps—for bubble‑free adhesion.

Stagger vertical seams at least 300 mm like brickwork; reduces stress lines by up to 40 % in vibration zones.

Integrate color‑matched trim to conceal raw edges and resist UV chalking.

Allow a full 24‑hour cure before installing shelving or heavy fixtures.

Photograph each wall after trimming; digital records speed warranty claims.

Schedule a 30‑day inspection to retorque fasteners—thermal cycling loosens 5 % of screws on average.

Case Study: Water‑Treatment Facility Retrofit

Challenge: Chlorine‑Rich Atmosphere & Downtime Limits

A Mid‑Atlantic utility had corroded concrete tunnels that had to stay online. Shutdown tolerance: one weekend.

Solution: Unicomposite Pultruded FRP Panels & Custom Flashings

Panels were factory‑notched and labeled, then delivered with prefab corner flashings. A six‑person crew installed 430 m² in 38 hours.

Results: 30 % Faster Install, Zero Corrosion After 2 Years

Plant maintenance reports show no delamination or blistering after continuous exposure to 200 ppm chlorine. “The smooth FRP wipes clean in minutes—far less labor than epoxy coatings,” notes the facility manager.

Maintenance & Long‑Term Performance

Routine Cleaning & Chemical Compatibility

Wash monthly with pH‑neutral detergent and a soft brush. Avoid sodium hypochlorite over 10 % concentration to keep the gel coat glossy.

Inspecting for Delamination & Fastener Loosening

Spot‑check corners and seams every quarter; re‑seal any hairline cracks with two‑part methacrylate.

Planning Future Upgrades with Modular FRP Profiles

Because FRP is non‑conductive and corrosion‑proof, many facilities bolt cable trays or pipe saddles directly onto existing panels later—saving wall demolition costs.

Conclusion

Proper planning, the right adhesive‑fastener combo, and the seven pro tips above turn FRP into a decades‑long shield against moisture, impact, and chemicals. Need help specifying thickness, resin, or custom shapes? Contact Unicomposite’s engineering team for bulk pricing and design assistance tailored to your plant’s environment.

Frequently Asked Questions

Q1. How long do FRP panels typically last in corrosive facilities?

With correct installation and routine cleaning, panels frequently exceed 25 years of service even in chlorine or salt‑spray atmospheres.

Q2. Can I install FRP over existing ceramic tile?

Yes, if the tile is sound, degreased, and mechanically abraded; use a high‑build adhesive and stainless fasteners to bridge grout lines.

Q3. What’s the minimum purchase quantity for custom colors or profiles?

Unicomposite can color‑match or modify profiles for orders of roughly 300 m² or more, depending on complexity and pigment availability.

Q4. How soon after installation can the room return to full production?

Most polyurethane adhesives reach holding strength within 24 hours at 21 °C and 50 % RH; cure time extends in colder, damper conditions.

Q5. Do FRP panels meet food‑contact regulations?

Gel‑coated sanitary‑grade panels can conform to USDA & FDA guidelines when manufactured with food‑safe resin systems—request certification from your supplier.

info@unicomposite.com

info@unicomposite.com