Introduction

Industrial plant managers, EPC contractors, and OEM engineers face a familiar dilemma: galvanized or stainless‑steel grating keeps rusting, crews keep fighting with its weight, and the maintenance budget keeps ballooning. The quest for a smarter alternative explains the surge of interest in fiberglass‑reinforced plastic (FRP) grating. This guide unpacks why choose FRP over metal grating is becoming the default decision, drawing on field feedback from Unicomposite—an ISO‑certified pultrusion manufacturer that produces custom composite panels for utility, wastewater, and OEM platforms across five continents.

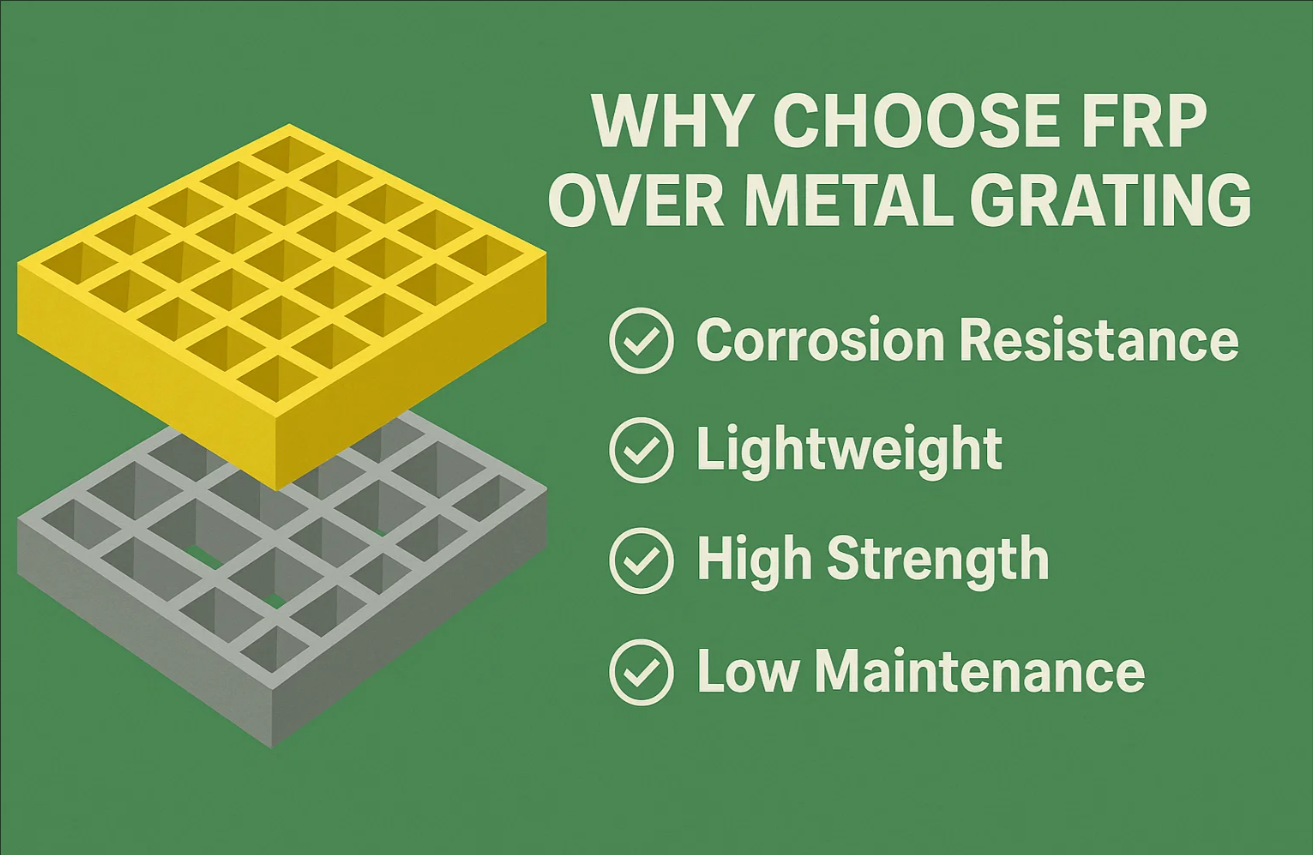

why choose frp over metal grating

The Limitations of Traditional Metal Grating

Corrosion & Rust in Harsh or Chemical Environments

Even the best zinc coatings eventually pit in salt spray or acidic wash‑down areas. NACE International pegs global corrosion losses at 3–4 % of GDP each year, and walkway grating is a repeat offender.

Heavy Weight and Difficult Handling During Installation & Retrofit Projects

Carbon‑steel bar grating typically weighs 10–12 lb/ft². Lifting a single 3 × 12 ft panel requires a two‑person crew or a hoist, driving up crane time and lost production hours during shutdowns.

Conductivity, Spark Risk, and Slip Hazards That Endanger Workers

Steel is conductive and can arc if dropped on energized equipment. Even serrated bars become slick when coated with oil or algae, increasing recordable incidents for slips, trips, and falls.

Lifecycle Cost Data: Annualized Maintenance vs. Replacement Cycles

A 2023 water‑treatment benchmarking study found that plants spending $150 k on new steel grating averaged another $85 k in recoating and fast‑track replacements within five years—nearly doubling the installed cost.

What Makes FRP Grating Different

Inside the Material: Fiberglass Reinforcement + Thermoset Resin Matrix

E‑glass rovings provide tensile strength while a vinyl‑ester or polyester resin bonds everything into a single, inert matrix. The American Composites Manufacturers Association reports that demand for industrial FRP grating has grown 6 % annually since 2018, largely because of this corrosion advantage.

How Pultrusion and Molded Processes Shape Performance Characteristics

Pultruded FRP—the specialty of Unicomposite—aligns continuous fibers along the load axis for superior span capability, whereas molded FRP offers multidirectional strength for wash‑down trenches.

Compliance With ASTM, OSHA, ISO, and Industry‑Specific Standards

Modern FRP panels meet ASTM F3059 for load and deflection, OSHA 1910.22 for walking‑working surfaces, and are produced in ISO‑9001 environments for full traceability.

7 Compelling Reasons to Choose FRP Over Metal Grating

Superior Corrosion Resistance for Wastewater, Marine, and Chemical Plants

Vinyl‑ester FRP shrugs off sodium hypochlorite, hydrogen sulfide, and brine where galvanized steel gives up in months. Many coastal facilities report 20‑year service lives without recoating.

Up to 70 % Lighter—Lower Crane Time, Faster Crew Productivity

A standard 1.5‑inch pultruded panel weighs just 3.7 lb/ft²—roughly 70 % lighter than steel. Crews routinely hand‑carry sections through man‑ways, cutting install time by one‑third on retrofit jobs.

Dielectric & Non‑Sparking Properties for Electrical and Oil & Gas Sites

With surface resistivity >10¹² Ω, FRP won’t ground stray current. Maintenance teams working around switchgear or cathodic‑protection cables appreciate the reduction in arc‑flash risk.

Built‑In Slip Resistance Even When Wet or Oily

Grit embedded during molding produces a coefficient of friction up to 0.63 wet, outperforming serrated steel (0.49). A Purdue University test series reported 30 % fewer slip events on FRP samples.

Minimal Maintenance and 20‑Plus‑Year Service Life (Total Cost of Ownership)

No painting, no hot‑works permits, and no special tools—just occasional pressure‑washing. When you spread acquisition cost over two decades, FRP’s net present cost can be 35 % lower than steel.

Design Flexibility: Colors, Mesh Sizes, Fire‑Retardant & UV‑Stable Options

Because the resin is pigmented in‑bulk, safety yellow or traffic gray colors never flake. Custom mesh (e.g., 38 × 38 mm, 19 × 19 mm) and ASTM E84 Class 1 fire retardance are common options from suppliers such as Unicomposite.

Sustainability Gains: No Toxic Coatings, Easier End‑of‑Life Recycling

Eliminating galvanizing baths slashes upstream emissions, and clean FRP scrap can be granulated into filler for composite decking or concrete, diverting waste from landfills.

Experience in Action: Anonymized Case Study

Project Snapshot—Municipal Wastewater Treatment Walkways

A Midwestern municipality upgraded 540 ft of aeration‑basin walkways originally built with carbon‑steel grating that corroded after three winters.

Transition From Carbon Steel to Unicomposite FRP Panels

The engineering firm specified 38 mm deep I‑bar pultruded FRP panels pre‑cut at Unicomposite’s Jiangsu factory. Panels arrived with stainless clips, allowing maintenance crews to install during a 48‑hour outage.

Quantified Results: 40 % Maintenance Cost Reduction Over Five Years

Plant records show zero coating repairs and only annual power‑washing. The project team calculated a $112 k saving versus staying with coated steel, validating the switch.

How to Specify the Right FRP Grating for Your Application

Define Load & Span Requirements Using Published Tables

Start with live load and deflection criteria. Pultruded I‑bar 38 mm panels, for example, can span 900 mm at 500 kg/m² with ≤ 6 mm deflection—check manufacturer tables.

Match Resin Formulations to Chemicals, Temperature, and UV Exposure

Select vinyl‑ester for 98 % sulfuric acid, phenolic for fire‑critical offshore modules, or food‑grade polyester for dairy wash‑downs.

Confirm Fire Ratings, Conductivity Limits, and Slip Coefficient Targets

Request independent ASTM E84, ASTM F1679, and ASTM D495 test reports. Spec sheets from Unicomposite include these values for easy vetting.

Collaborate With a Qualified FRP Partner for Custom Shapes & Bulk Orders

Early dialog with an experienced pultruder allows nesting panel sizes to maximize container loads and integrating kick‑plates or prefabricated stair treads.

Conclusion

Steel grating served industry well—until corrosion, weight, electrical hazards, and rising labor costs forced a rethink. FRP’s unmatched corrosion resistance, 70 % weight savings, dielectric safety, and two‑decade lifespan deliver measurable ROI on the plant floor. Talk with the engineering team at Unicomposite to review drawings, receive material samples, or secure a fast RFQ that moves your project forward.

Frequently Asked Questions

Q1. How does FRP grating handle extreme temperatures?

Continuous service limits range from –40 °C to 120 °C depending on resin; pultruders can tweak formulations for brief thermal spikes.

Q2. Can FRP panels be cut on‑site?

Yes—use a carbide‑tipped circular saw and wear a dust mask; edges should be sealed with resin to maintain corrosion resistance.

Q3. What is the typical lead time for bulk orders?

Standard profiles ship in 3–4 weeks; custom colors or fire‑rated resins may add one additional week for tooling and cure validation.

Q4. Is FRP grating recyclable?

Clean offcuts can be ground into filler for new composite goods or used as energy‑rich feedstock in cement kilns, keeping waste out of landfills.

Q5. Does FRP meet slip‑resistance codes?

Embedded grit surfaces routinely exceed the ANSI A1264.2 recommendation of 0.5 static coefficient of friction, even under wet conditions.

info@unicomposite.com

info@unicomposite.com