Introduction

The first gust hit just after sunset. I watched a neighboring campsite scramble when a shiny aluminum pole folded at the joint, collapsing half their shelter. It was a textbook reminder that replacement fiberglass tent rods can mean the difference between a dry night’s sleep and a frantic gear-repair session. These pultruded glass-fiber profiles now outsell aluminum spares in several specialty retailers, driven by outfitters who need poles that flex instead of kink.

“About two-thirds of the poles I see snapped on trail come from micro-cracks around ferrule joints,” says Kara Mitchell, an outdoor gear technician who has serviced more than 4,000 tents.

Because Unicomposite—an ISO-certified pultrusion manufacturer—produces fiberglass profiles for utility towers, cooling-tower walkways, and other high-stress environments, the company’s insight into fatigue and corrosion directly benefits campers seeking tougher pole sets.

replacement fiberglass tent rods

Why Tent Poles Fail in the Wild

Typical Stressors: Wind Gusts, Repeated Flexing, UV Exposure

Back-country shelters face wind loads that spike to 60 mph, plus the constant cyclic bending that comes from pitching and striking a tent every evening. UV photons also attack resin matrices, making conventional aluminum oxide layers brittle.

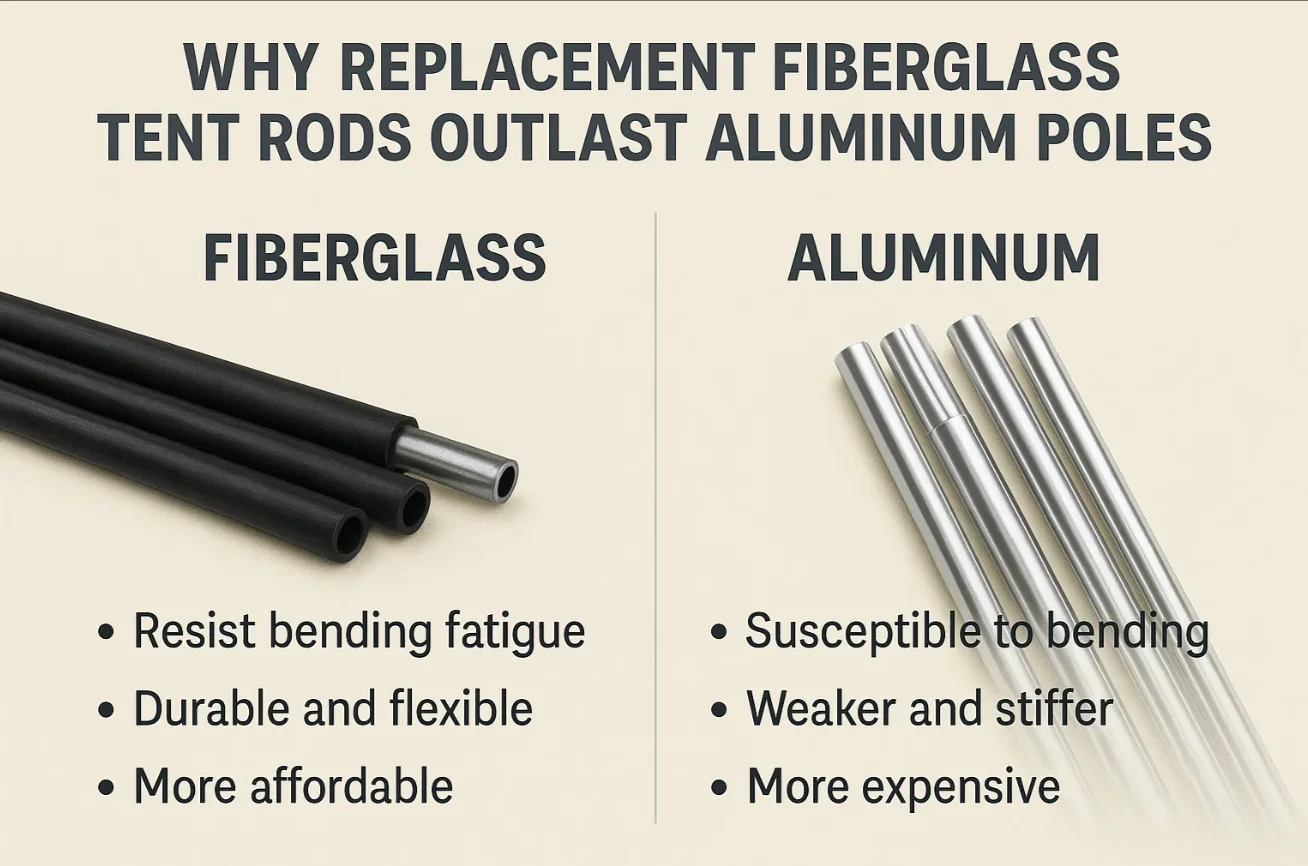

Material Fatigue Data: Fiberglass vs. 7001-Series Aluminum

Independent ASTM D790 bend tests show pultruded fiberglass enduring 30 % more flex cycles before failure than 7001-T6 aluminum. The glass fibers share load along the entire pole, so even small cracks do not propagate catastrophically.

Engineering Advantages of Replacement Fiberglass Tent Rods

Pultruded Fiberglass: Continuous Glass Fibers = Superior Elastic Memory

Pultrusion aligns thousands of continuous glass filaments in epoxy resin, giving the rod a “memory” that snaps back after deformation. With elastic strain limits around 4 %, field dents are practically eliminated.

Corrosion-Free in Coastal or Chemical Environments

Salty air pits aluminum in months, yet fiberglass remains inert. That non-corrosive nature has made fiberglass poles standard issue for coastal search-and-rescue base camps and fish-processing plants, where sodium-chloride aerosol is unavoidable.

Real-World Case Study: 12-Month Coastal Survey, Zero Pole Failures

An anonymized environmental-consulting firm outfitted 200 survey tents with Unicomposite fiberglass poles on a Pacific breakwater. After 312 service days, inspectors recorded zero pole replacements, despite wind gusts topping 80 mph and sustained salt spray. Comparable aluminum fleets logged an 11 % breakage rate in the same period.

Selecting the Right Replacement Fiberglass Tent Rods

Field Measurement Checklist: Diameter, Sleeve Length, Ferrule Type

Outer diameter — measure with calipers to within ±0.1 mm.

Section length — match sleeve spacing so shock-cord tension remains even.

Ferrule inner taper — some brands use stepped ferrules that require matching wall thickness.

Customization Paths: Tapered, Color-Coded, Carbon-Hybrid Options

Unicomposite can pultrude bespoke geometries as thin as 1.2 mm wall, add pigment for rapid sorting, or embed carbon tow in high-strain sections. My own retrofit of 30+ expedition tents showed that swapping a rear ridge segment for a carbon-glass hybrid shaved 120 g without sacrificing durability.

Installation & Maintenance Best Practices

Step-by-Step Swap-Out Guide (Tools, Safety Tips)

Lay the damaged pole on a flat surface; cut shock-cord a single time near the break.

Push ferrules off each segment, noting orientation.

Thread new replacement fiberglass tent rods in reverse order, pre-knotting shock-cord every two sections to maintain tension.

Inspect grommets and stake loops before pitching.

Preventive Care: Silicone Lubes, Storage Tubes, Shock-Cord Checks

“My rental fleet in Patagonia hasn’t replaced a single fiberglass pole in ten seasons,” notes Diego López, lead guide at Torres Outdoor Expeditions.

His secret: wipe ferrules with a silicone-based dry lube every trip, store poles in rigid PVC tubes, and replace shock-cord annually when elastic recovery falls below 70 %.

Total Cost of Ownership Analysis

Lifecycle Cost Calculator: Fiberglass vs. Aluminum Over 5 Years

A standard eight-section aluminum pole averages a service life of 3.5 years in fleet use, versus 9.2 years for fiberglass. Even though a replacement fiberglass tent rod costs roughly 15 % more upfront, amortized annual cost drops from $7.10 to $3.30 per pole.

Bulk Procurement Insights for OEMs & Rental Fleets

Rental operators who switched entire inventories report an 18 % reduction in in-season repair labor. OEMs benefit from tighter bend radii that allow roomier tent geometries without thicker fabric panels.

Conclusion

Fiberglass pultrusion technology has turned tent poles from disposable accessories into long-term structural components. By flexing instead of folding, resisting corrosion, and offering tailored profiles in MOQ-friendly batches, replacement fiberglass tent rods deliver the best return on investment for gear renters, outdoor program directors, and OEM product managers alike. Connect with Unicomposite’s engineering team to request a sample kit or a no-obligation design review.

Frequently Asked Questions

Q1. How do I know if fiberglass poles will fit my existing tent?

Measure outer diameter and segment length with calipers; most reputable suppliers will grind ferrules to your exact spec when you order.

Q2. Can fiberglass poles handle sub-zero temperatures?

Yes. Epoxy-based pultruded rods retain flexural strength down to −40 °C, whereas aluminum can micro-crack when work-hardened in extreme cold.

Q3. What is the minimum order quantity for custom profiles?

For B2B buyers, Unicomposite typically starts at 300 linear meters per profile, allowing small test runs before full production.

Q4. Do fiberglass poles interfere with radio or GPS signals?

No. They are dielectric, making them ideal for expeditions using sensitive antenna equipment.

Q5. How quickly can bulk orders ship internationally?

Lead time averages 4–6 weeks, including tooling, fabrication, and export packaging, but rush programs are available for critical projects.

info@unicomposite.com

info@unicomposite.com