Introduction

When it comes to industrial flooring, walkways, or platforms, safety and durability are of paramount importance. Among the various grating materials available, expanded fiberglass grating has gained popularity for its outstanding characteristics. This article aims to guide you through the process of choosing the best-expanded fiberglass grating for your specific needs, highlighting its advantages, factors to consider, and applications.

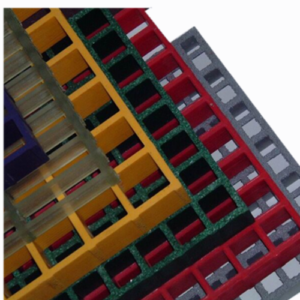

expanded fiberglass grating

What is Expanded Fiberglass Grating?

Expanded fiberglass grating is a type of reinforced plastic grating made from fiberglass strands and resin. The manufacturing process involves thermally bonding the strands, creating an open grid pattern that results in a strong and lightweight structure. This unique construction offers several advantages that make it a preferred choice in various industries.

Advantages of Expanded Fiberglass Grating

Before delving into the selection process, it’s essential to understand the benefits of expanded fiberglass grating. These advantages include:

- High Strength-to-Weight Ratio: Expanded fiberglass grating is incredibly strong despite its lightweight nature, making it suitable for applications with heavy loads.

- Corrosion and Chemical Resistance: Unlike metal grating, fiberglass is highly resistant to corrosion and chemical attacks, making it ideal for environments with harsh substances.

- Slip-Resistant Surface: The open grid design provides excellent traction, reducing the risk of slips and falls, even in wet conditions.

- UV Resistance: Expanded fiberglass grating is UV resistant, ensuring its color and structural integrity remain intact even when exposed to sunlight.

- Electrical and Thermal Insulation: Fiberglass does not conduct electricity and has low thermal conductivity, making it safe to use in electrical and heat-sensitive environments.

- Low Maintenance: Its durable composition requires minimal maintenance, saving time and costs in the long run.

Factors to Consider When Choosing Expanded Fiberglass Grating

To select the right expanded fiberglass grating for your project, consider the following factors:

1. Load-Bearing Capacity

Determine the weight the grating will bear. The grating’s load-bearing capacity should exceed the maximum weight it will support.

2. Chemical Resistance

Evaluate the environment in which the grating will be installed. Choose a grating that can withstand exposure to chemicals and corrosive substances present in that setting.

3. Anti-Slip Properties

Consider the level of traction required for safety. Anti-slip coatings or surfaces are essential for areas prone to moisture or oil spillage.

4. Durability and Longevity

Invest in high-quality grating that can endure heavy usage and harsh conditions without losing structural integrity.

5. Installation and Maintenance

Choose a grating that is easy to install and requires minimal maintenance efforts, reducing downtime and expenses.

6. Cost-Effectiveness

Balance the upfront cost with the long-term benefits and durability to ensure a cost-effective solution.

7. Customization Options

Look for suppliers that offer customization options in terms of size, color, and other specifications to meet your project’s unique requirements.

Comparing Expanded Fiberglass Grating with Other Materials

To make an informed decision, compare expanded fiberglass grating with other common grating materials:

5.1. Steel Grating

While steel grating is strong, it is prone to corrosion, making it unsuitable for corrosive environments.

5.2. Aluminum Grating

Aluminum grating is lightweight and corrosion-resistant but may not be as strong as fiberglass.

5.3. Pultruded Fiberglass Grating

Pultruded fiberglass grating is also an option, but it lacks the open grid design, reducing its slip-resistance.

Applications of Expanded Fiberglass Grating

Expanded fiberglass grating finds applications in various industries, including:

6.1. Industrial Flooring

Its strength and chemical resistance make it ideal for use as flooring in industrial facilities.

6.2. Walkways and Platforms

Expanded fiberglass grating provides safe walkways and platforms in both indoor and outdoor settings.

6.3. Stair Treads

It offers slip-resistant stair treads, enhancing safety in stairways.

6.4. Drain Covers

The open grid design allows for efficient drainage, making it suitable for drain covers.

6.5. Catwalks and Bridges

Expanded fiberglass grating is commonly used in catwalks and pedestrian bridges.

6.6. Chemical Processing Plants

Its chemical resistance makes it a reliable choice in chemical processing plants.

6.7. Marine Environments

Due to its corrosion resistance, it is widely used in marine environments and offshore structures.

How to Select the Right Expanded Fiberglass Grating

Choosing the right expanded fiberglass grating involves analyzing your project’s specific requirements and comparing different options based on load-bearing capacity, chemical resistance, anti-slip properties, durability, ease of installation, and customization options. It’s crucial to work with reputable suppliers who offer high-quality products and provide expert guidance throughout the selection process.

Conclusion

Expanded fiberglass grating is an excellent choice for various industrial applications due to its exceptional properties, including high strength, chemical resistance, slip resistance, and low maintenance. When selecting the right expanded fiberglass grating, consider the factors mentioned earlier to ensure safety, durability, and cost-effectiveness.

FAQs

- Is expanded fiberglass grating suitable for outdoor use?

- Yes, expanded fiberglass grating is UV resistant and can withstand outdoor conditions effectively.

- Can expanded fiberglass grating support heavy loads?

- Absolutely, expanded fiberglass grating has a high strength-to-weight ratio and can handle heavy loads.

- How does expanded fiberglass grating compare to steel grating in terms of corrosion resistance?

- Expanded fiberglass grating surpasses steel grating in terms of corrosion resistance, making it ideal for corrosive environments.

- Does expanded fiberglass grating require specialized installation?

- Expanded fiberglass grating is relatively easy to install, but it’s recommended to consult with professionals for precise installation.

- Can I customize the color and size of expanded fiberglass grating?

- Yes, Unicomposite composite profiles offer customization options for color, size, and other specifications to meet your project’s needs.

info@unicomposite.com

info@unicomposite.com