Introduction

When it comes to choosing the right grating option for your project, it’s essential to consider various factors such as durability, safety, maintenance, and cost-effectiveness. In this article, Unicomposite composite profiles will compare Duragrate fiberglass grating to other popular grating options available in the market. By understanding the pros and cons of each type, you can make an informed decision that best suits your requirements.

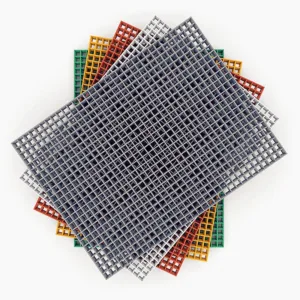

duragrate fiberglass grating

Understanding Fiberglass Grating

Fiberglass grating is a versatile and durable material used in various industrial and commercial applications. It is made by combining glass fibers with resin, resulting in a lightweight yet strong product. Fiberglass grating offers excellent resistance to corrosion, chemicals, and extreme temperatures. It also provides a high strength-to-weight ratio, making it an ideal choice for applications where weight is a concern.

Duragrate Fiberglass Grating

Duragrate fiberglass grating is a leading option within the fiberglass grating category. It offers exceptional strength, durability, and resistance to corrosion. Duragrate grating is manufactured with a pultrusion process that ensures uniformity and consistent mechanical properties. This type of grating is available in a variety of sizes, shapes, and surface options to meet specific project requirements.

Comparison with Metal Grating

Metal grating, such as steel or aluminum, is a popular choice due to its strength and rigidity. However, compared to Duragrate fiberglass grating, metal grating has several drawbacks. Metal grating is prone to corrosion, especially in humid or corrosive environments. It requires regular maintenance, including painting or coating to prevent rust. Additionally, metal grating is heavier, making it more challenging to handle and install.

Comparison with Wooden Grating

Wooden grating is often used in non-industrial applications due to its natural aesthetic appeal. While wooden grating may be suitable for some projects, it has limitations compared to Duragrate fiberglass grating. Wooden grating is susceptible to rot, decay, and insect damage, especially when exposed to moisture. It also requires regular maintenance, such as sealing or staining, to prolong its lifespan.

Comparison with Concrete Grating

Concrete grating is known for its strength and durability. However, it has certain disadvantages when compared to Duragrate fiberglass grating. Concrete grating is heavy and requires specialized equipment for installation, increasing labor and transportation costs. It is also prone to cracking, especially in environments with temperature fluctuations. Concrete grating may not be suitable for areas where weight restrictions are a concern.

Pros and Cons of Duragrate Fiberglass Grating

Duragrate fiberglass grating offers several advantages and a few considerations to keep in mind. Here are the pros and cons of choosing Duragrate fiberglass grating for your project:

Pros:

- Excellent corrosion resistance.

- Lightweight and easy to handle.

- Low maintenance requirements.

- Slip-resistant surface options available.

- Electrical and thermal insulation properties.

- Wide range of customization options.

Cons:

- Higher initial cost compared to some grating options.

- Limited load-bearing capacity in heavy-duty applications.

Conclusion

When comparing Duragrate fiberglass grating to other grating options, it becomes evident that Duragrate offers a compelling set of advantages. Its corrosion resistance, lightweight nature, low maintenance requirements, and customization options make it an excellent choice for many applications. However, it’s essential to consider specific project needs and load requirements before making a final decision.

FAQs

- Is Duragrate fiberglass grating suitable for outdoor applications? Yes, Duragrate fiberglass grating is highly suitable for outdoor applications due to its excellent corrosion resistance.

- Can Duragrate fiberglass grating withstand heavy loads? Duragrate grating has a limited load-bearing capacity, so it may not be suitable for extremely heavy-duty applications. It’s important to consult the manufacturer’s load tables for specific information.

- How do I maintain Duragrate fiberglass grating? Duragrate grating requires minimal maintenance. Regular cleaning with mild detergent and water is usually sufficient to keep it in good condition.

- Can Duragrate grating be customized to fit specific project requirements? Yes, Duragrate fiberglass grating can be customized in terms of size, shape, color, and surface options to meet the unique needs of your project.

- Is Duragrate grating safe to walk on? Yes, Duragrate grating offers slip-resistant surface options, making it safe to walk on even in wet or oily conditions.

info@unicomposite.com

info@unicomposite.com