We all know that FRP grids can be applied to sidewalks or elevated platforms, docks, chemical plants, water plants, and wastewater. So is it expensive to lay sidewalks with fiberglass grids? This article will compare steel grating and aluminum grating for you, and understand whether the cost of laying fiberglass grating sidewalks is high.

Application and characteristics of FRP grating

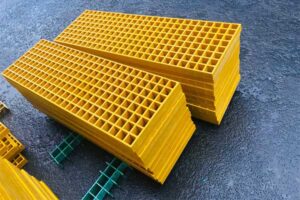

FRP grating is a composite material made of resin as a matrix and glass fiber. FRP grating does not corrode like steel grating, so it is used in corrosive environments to reduce maintenance costs. It is used in a variety of applications including walkways and raised platforms. FRP grating is a load-bearing structural product between spans.

Application and characteristics of steel grating

The surface of the welded steel grating is non-slip, corrosion-resistant, has good drainage performance, high strength, and strong bearing capacity. Therefore, it is widely used as walkways, stairs, fences, shelves, ceilings, and floors in many places. WSG-1: Stainless steel welded steel grating with a smooth surface.

Application and characteristics of aluminum grating

Corrosion-resistant, non-sparking, and non-rusting aluminum gratings are widely used for their lightweight and high strength. Ideal for use in corrosive environments, it is widely used as walkways and platforms in sewage treatment plants, oil refineries, chemical processing plants, pump and compressor stations, and on ships and barges. Because it does not rust, it is commonly used in breweries, bottling plants, and food preparation and storage facilities. Its non-sparking properties make it a safety necessity in munitions factories and other unstable industries and locations. It is available in standard or anodized finishes. The aluminum grating is designed as a high-strength, lightweight product, using an I-beam or rectangular load-bearing steel bar, and the crossbar is forged by high-pressure hydraulic pressure.

From the perspective of application and characteristics, it is very important for us to choose the material according to the specific application environment, and the second is to consider the cost. Generally, the cost depends on many factors. You have to choose the type of grating from the different available categories depending on where the bar grating will be used and the cost will vary. On the other hand, the selected material, size, quality, and brand also have a great relationship with the grille cost.

In addition, the approximate price on the market is that the standard size of heavy-duty steel grating costs about $1,500 to $1,800 per ton; the price of the aluminum grating is $50 a piece; the price of fiberglass grating is $45 per square meter.

The above is a detailed introduction to the cost of laying fiberglass grid sidewalks. From the perspective of the use environment, fiberglass grids are relatively cost-effective. If you want to continue to understand the quotation about FRP grating, welcome to contact us!

info@unicomposite.com

info@unicomposite.com