When it comes to ensuring the safety and efficiency of industrial sites, choosing the right materials for grating and trench covers is crucial. Among the many options available, pultruded fiberglass grating stands out for its durability, corrosion resistance, and easy installation. In this article, we will explore the benefits of using pultruded fiberglass grating to safeguard draining trenches in various industrial settings.

What is Pultruded Fiberglass Grating?

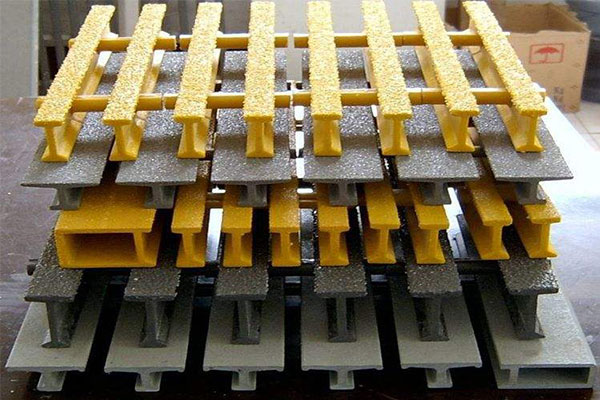

Pultruded fiberglass grating is a type of composite material that is made by pulling continuous glass fibers through a resin bath and then heating and shaping them in a mold. The resulting product is strong, lightweight, and resistant to corrosion, chemicals, and fire. Unlike steel or aluminum grating, which can corrode and deteriorate over time, pultruded fiberglass grating requires minimal maintenance and can last for decades.

How Does Pultruded Fiberglass Grating Protect Draining Trenches?

Draining trenches are essential for directing liquids and debris away from work areas, and preventing slips, falls, and accidents. However, they can also pose a hazard if they are left uncovered or if the covers are not secure. This is where pultruded fiberglass grating comes in. By using pultruded fiberglass grating to cover the draining trench, you can ensure that:

- The grating is slip-resistant: Pultruded fiberglass grating has a high coefficient of friction, meaning it provides a non-slip surface that reduces the risk of slips and falls, even when wet or oily.

- The grating is load-bearing: Pultruded fiberglass grating can support heavy loads without deforming or breaking. This makes it ideal for covering draining trenches that are exposed to heavy equipment, vehicles, or foot traffic.

- The grating is corrosion-resistant: Unlike steel or aluminum grating, which can rust or corrode over time, pultruded fiberglass grating is highly resistant to chemicals, saltwater, and other corrosive substances. This ensures that the grating remains stable and safe for use in harsh environments.

- The grating is easy to install: Pultruded fiberglass grating is lightweight and easy to handle, which makes it faster and more cost-effective to install than other materials. It can also be cut to size on-site, eliminating the need for complicated fabrication or welding.

- The grating is customizable: Pultruded fiberglass grating comes in various sizes, shapes, and colors, which allows you to customize the cover to your specific needs and requirements.

Where Can Pultruded Fiberglass Grating Be Used?

Pultruded fiberglass grating is versatile and can be used in various industrial settings where draining trenches are required. Some common applications include:

- Chemical processing plants: Pultruded fiberglass grating is resistant to a wide range of chemicals, making it ideal for use in areas where corrosive substances are present.

- Food and beverage facilities: Pultruded fiberglass grating is hygienic and easy to clean, which makes it suitable for use in food processing and packaging areas.

- Power and energy plants: Pultruded fiberglass grating can withstand extreme temperatures and harsh weather conditions, making it a reliable choice for power generation facilities and outdoor substations.

- Marine and offshore environments: Pultruded fiberglass grating is resistant to saltwater and UV radiation, making it ideal for use in marinas, docks, and offshore platforms.

- Transportation and logistics: Pultruded fiberglass grating can be used to cover drainage trenches in airports, train stations, and shipping terminals, where heavy equipment and frequent foot traffic are common.

Unicomposite and Draining Trench Safety Solution

Pultruded fiberglass grating from Unicomposite is a reliable and cost-effective solution. By using pultruded fiberglass grating to cover the draining trench, industries can ensure slip resistance, load-bearing capacity, and corrosion resistance.

info@unicomposite.com

info@unicomposite.com