Introduction:

When it comes to industrial flooring and walkways, quality matters. Ensuring the safety and durability of such installations is crucial for any organization. In recent years, fiberglass grating has emerged as a popular choice for many industries due to its exceptional qualities. This article Unicomposite pultruded profiles will explore the importance of quality in fiberglass grating and provide insights into where to buy premium fiberglass grating for your specific needs.

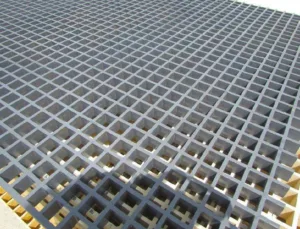

buy fiberglass grating

Understanding Fiberglass Grating:

Fiberglass grating is a composite material made from a combination of glass fibers and resin. The fibers provide reinforcement and strength, while the resin binds them together, resulting in a lightweight yet robust product. This unique composition offers several advantages over traditional materials such as steel or wood.

One of the key benefits of fiberglass grating is its excellent corrosion resistance. Unlike metals that can rust or wood that can rot, fiberglass grating is impervious to moisture and most chemicals. This makes it highly suitable for environments where exposure to harsh substances or corrosive agents is common, such as chemical plants or wastewater treatment facilities.

Furthermore, fiberglass grating offers impressive strength-to-weight ratio, making it a viable alternative to steel grating. Its lightweight nature allows for easier installation, reducing labor costs and time. Additionally, fiberglass grating is non-conductive and non-magnetic, making it ideal for use in electrical and magnetic-sensitive areas.

Factors to Consider When Buying Fiberglass Grating:

To ensure you purchase premium fiberglass grating that meets your specific requirements, there are several factors you should consider.

Firstly, it is essential to check if the fiberglass grating complies with relevant quality standards and certifications. Look for products that have been tested and certified by recognized organizations to guarantee their performance and reliability.

Secondly, assess the load-bearing capacity and durability of the fiberglass grating. Consider the maximum weight it can support and the expected lifespan of the product. Premium fiberglass grating should be able to withstand heavy loads and provide long-lasting performance.

Chemical and corrosion resistance is another critical aspect to evaluate. Depending on your industry, fiberglass grating may be exposed to various chemicals, acids, or alkalis. Ensure the grating you choose can withstand such exposures without deteriorating or losing its structural integrity.

In terms of safety, look for fiberglass grating with appropriate slip resistance features. This is particularly important in areas where moisture or oil can create slippery surfaces. Choose grating with a suitable coefficient of friction to prevent accidents and ensure the well-being of your employees or visitors.

Where to Buy Premium Fiberglass Grating:

Finding the right supplier is crucial when purchasing premium fiberglass grating. Consider the following steps to make an informed decision:

- Research reputable suppliers: Look for established companies that specialize in fiberglass grating and have a solid track record in the industry, such as Unicomposite.

- Check customer reviews and testimonials: Read feedback from previous customers to gauge the supplier’s reputation and customer satisfaction.

- Evaluate warranties and guarantees: Premium fiberglass grating suppliers often offer warranties or guarantees, indicating their confidence in the quality and durability of their products.

- Compare prices and delivery options: Request quotes from multiple suppliers and compare prices. Also, consider the delivery options and whether they align with your project timeline.

- Consider after-sales support and technical assistance: Choose a supplier that provides excellent customer service, including technical assistance during installation and ongoing support.

Benefits of Buying Premium Fiberglass Grating:

Investing in premium fiberglass grating offers numerous benefits for your organization:

- Long-term cost savings: While the initial investment may be higher than other materials, the long lifespan and minimal maintenance requirements of fiberglass grating result in cost savings over time.

- Enhanced safety and reliability: The slip resistance and durable nature of premium fiberglass grating ensure a safe environment for workers and visitors, reducing the risk of accidents.

- Customization options: Premium suppliers often offer customization options to meet specific project requirements, including size, color, and surface texture.

- Low maintenance requirements: Unlike steel grating that requires regular painting or wood grating that needs staining, fiberglass grating requires minimal maintenance, saving time and effort.

- Environmentally friendly choice: Fiberglass grating is a sustainable option as it is recyclable and does not contribute to deforestation or require harmful chemicals for maintenance.

Conclusion:

In conclusion, the importance of quality cannot be overstated when it comes to purchasing fiberglass grating for industrial applications. Considering factors such as certifications, load-bearing capacity, chemical resistance, and safety features will help you make an informed decision. By researching reputable suppliers, comparing prices, and evaluating customer reviews, you can find the right supplier for premium fiberglass grating that meets your specific needs. Investing in high-quality fiberglass grating will result in long-term cost savings, enhanced safety, and a reliable flooring solution for your organization.

FAQs

- Is fiberglass grating suitable for outdoor applications?

- Yes, fiberglass grating is highly suitable for outdoor applications as it is resistant to UV radiation, moisture, and temperature variations.

- Can fiberglass grating be painted or coated?

- Yes, fiberglass grating can be painted or coated to enhance its appearance or provide additional protection.

- How do I determine the appropriate load rating for my project?

- The load rating depends on factors such as the anticipated weight and type of traffic. Consult with the supplier or refer to load tables provided by manufacturers to determine the suitable load rating.

- Are there any specific installation requirements for fiberglass grating?

- Fiberglass grating installation typically involves securing it to a supporting structure using clips or fasteners. Follow the manufacturer’s installation guidelines for best results.

- Can fiberglass grating be recycled?

- Yes, fiberglass grating can be recycled, making it an environmentally friendly choice compared to other materials. Contact local recycling facilities for proper disposal methods.

info@unicomposite.com

info@unicomposite.com