When working with construction and engineering materials, one often comes across fiberglass angles. Understanding their weight is crucial for various applications, from design considerations to transportation logistics. In this article, we will explore what fiberglass angle weight means, why it matters, and how it can affect your projects.

fiberglass angle weight

What is a Fiberglass Angle?

A fiberglass angle is a structural component made from fiberglass-reinforced plastic (FRP). It typically has an L-shaped cross-section and is known for its high strength, durability, and resistance to corrosion. These properties make it a popular choice in industries such as construction, marine, and chemical processing.

Why is Fiberglass Angle Weight Important?

- Design and Engineering: The weight of a fiberglass angle affects the overall weight of the structure it is part of. Lighter materials can reduce the load on supporting structures, which can be particularly important in applications where weight is a critical factor, such as in aerospace or automotive industries.

- Installation and Handling: Lighter fiberglass angles are easier to handle, transport, and install. This can lead to cost savings in terms of labor and equipment required for installation.

- Cost Efficiency: The weight of the fiberglass angle can impact shipping costs. Lighter materials generally cost less to ship, which can be a significant consideration for large-scale projects.

- Performance Characteristics: The weight of the fiberglass angle can influence its mechanical properties. For example, heavier angles might offer more stability and support in certain applications, while lighter ones might be preferable in scenarios where flexibility and ease of use are prioritized.

Factors Influencing Fiberglass Angle Weight

Several factors determine the weight of a fiberglass angle:

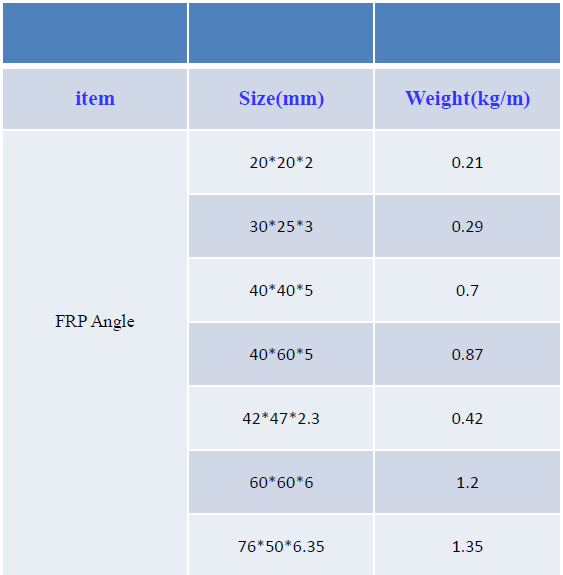

- Dimensions: The length, width, and thickness of the fiberglass angle directly impact its weight. Larger dimensions result in a heavier angle.

- Density of Materials: The type of resin and the amount of fiberglass reinforcement used in the composite material affect its density and, consequently, its weight.

- Manufacturing Process: Different manufacturing techniques can result in variations in the weight of the final product. For example, pultrusion, a common method for producing fiberglass angles, ensures consistent weight and quality.

Calculating Fiberglass Angle Weight

To calculate the weight of a fiberglass angle, you can use the following formula:

Weight=Volume×Density\text{Weight} = \text{Volume} \times \text{Density}

Where:

- Volume is determined by the dimensions of the angle (length, width, thickness).

- Density is the mass per unit volume of the fiberglass material, usually provided by the manufacturer.

For example, if you have a fiberglass angle with dimensions 10 feet in length, 2 inches in width, and 0.25 inches in thickness, and the material density is 0.065 pounds per cubic inch, you can calculate the volume and then the weight accordingly.

Conclusion

Understanding the weight of fiberglass angles is essential for making informed decisions in various industrial applications. It affects design, handling, cost efficiency, and performance. By considering the factors that influence weight and how to calculate it, you can better plan and execute your projects involving fiberglass angles.

Remember, always refer to manufacturer specifications for accurate density values and consult with experts when in doubt. Proper planning and knowledge of material properties will ensure the success of your projects.

info@unicomposite.com

info@unicomposite.com