Introduction: Navigating the World of Fiberglass Grid Grating

In the realm of construction and industrial projects, the right materials make all the difference. When it comes to choosing the best fiberglass grid grating for your project, a strategic decision can significantly impact the outcome. Let’s delve into the key factors that will guide you towards the optimal choice.

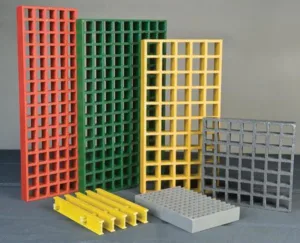

fiberglass grid grating

Understanding Your Project Needs

Before diving into the world of fiberglass grid grating, assess your project’s unique requirements. Identify factors such as load capacity, corrosion resistance, and environmental conditions. This initial step sets the stage for a tailored selection process.

Exploring Fiberglass Grid Grating Types

Molded or Pultruded: Which Suits Your Project?

Molded Fiberglass Grid Grating: For projects requiring a balance of strength and cost-effectiveness, molded grating proves to be a solid choice. Its versatile design accommodates various applications without compromising durability.

Pultruded Fiberglass Grid Grating: If your project demands enhanced load-bearing capabilities, pultruded grating takes the lead. With a reinforced structure, it excels in heavy-duty scenarios, making it ideal for industrial settings.

Considering Resin Types: A Critical Decision

Polyester, Vinyl Ester, or Phenolic: Decoding the Resin Dilemma

Polyester Resin: Balancing cost and performance, polyester resin is an excellent choice for projects with moderate chemical exposure. It offers durability without breaking the bank.

Vinyl Ester Resin: Stepping up the chemical resistance game, vinyl ester resin is perfect for environments where corrosive substances pose a constant threat. Its enhanced durability makes it a preferred option for demanding applications.

Phenolic Resin: In situations where fire resistance is paramount, phenolic resin emerges as the hero. Its ability to withstand high temperatures adds an extra layer of safety to your project.

Weaving Through Load Capacities: Matching Strength to Requirements

Considering the load capacity is non-negotiable when selecting fiberglass grid grating. Whether it’s pedestrian foot traffic or heavy equipment, ensure the chosen grating can bear the load without compromise.

Environmental Factors: The Unsung Heroes of Decision-Making

Adapting to environmental conditions is crucial for long-term success. Fiberglass grid grating that withstands temperature fluctuations, UV exposure, and moisture ensures longevity and minimizes maintenance needs.

Conclusion: Your Blueprint to Success

Choosing the best fiberglass grid grating for your project boils down to understanding your unique needs and selecting materials that align with them. From resin types to load capacities, every decision plays a crucial role in the project’s success. By navigating these considerations, you pave the way for a seamless and durable outcome. Make your project stand out with the right fiberglass grid grating – a decision that speaks volumes in structural excellence.

info@unicomposite.com

info@unicomposite.com