Fiberglass Rebar is made of high strength glass fibersalong with an extremely durable resin via pultrusion process.

High-performance fiber is the reinforcing material, and synthetic resin is the matrix material. The fiber has high tensile strength and is the main provider of the strength of fiber-reinforced composite materials, which mainly plays the role of bearing load. Mainly divided into carbon fiber, aramid fiber, basalt fiber, glass fiber, etc.

The matrix material has the function of bonding and transmitting shear force, and its physical properties can affect the physical properties of fiber-reinforced materials.

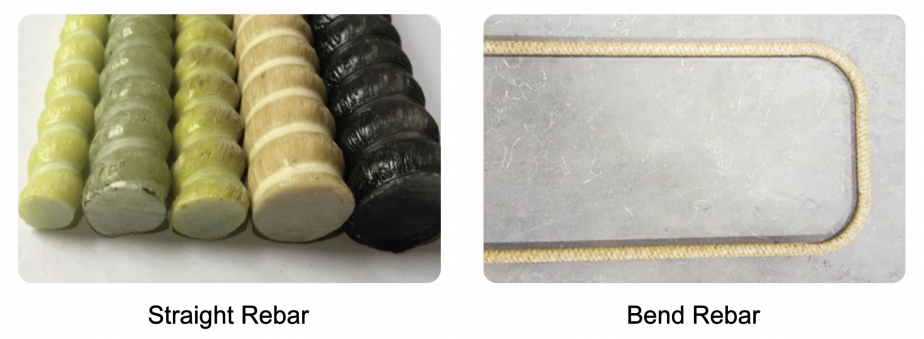

Diameter can be various from 4mm to 40mm, and the FRP rebar could be straight rebar or bending rebar.

GFRP Rebar is Widely Used Due to the Following Features:

- High Tensile Strength: The tensile strength is better than ordinary steel, 20% higher than that of steel bars of the same specification, and has good fatigue resistance;

- Light Weight: Only 1/4 of the same volume of steel bars, density between 1.5-1.9 (g/cm3);

- Strong Corrosion Resistance: The corrosion resistance of chemicals such as acid and alkali can resist the erosion of chloride ions and low PH value solutions, especially the corrosion resistance of carbon compounds and chlorine compounds;

- Strong Material Bonding Force: The thermal expansion coefficient is closer to cement than steel, so the bonding force of FRP reinforcement and concrete is stronger;

- Strong Designability: Stable elastic modulus. Dimensional stability under thermal stress, bending and other shapes can be arbitrarily thermoformed;

- Good Safety Performance: Non-thermal, non-conductive, flame-retardant and anti-static, no sparks will be generated by collision with metal through formula changes;

- Strong Magnetic Wave Permeability: FRP reinforcement is a non-magnetic material, and does not need to be demagnetized in non-magnetic or electromagnetic concrete components;

- Convenient Construction: Standard and non-standard parts with different sections and lengths can be produced according to user requirements, and U-shaped buckles can be used for on-site binding, which is easy to operate.

Application:

- It can be widely used in highways, bridges, airports, docks, stations, water conservancy projects, underground engineering and other fields.

- Suitable for use in corrosive environments such as sewage treatment plants, chemical plants, electrolyzers, luxury manhole covers, and coastal defense projects.

- It is suitable for use in military engineering, security engineering, special engineering and other environments that require insulation and demagnetization.

info@unicomposite.com

info@unicomposite.com