Fiberglass structural tubing is a popular material choice for a wide range of applications, including construction, automotive, and marine industries. It is known for its high strength, durability, and corrosion resistance, making it a highly versatile material that can withstand harsh environments and conditions. In this essay, we will explore some of the key advantages of fiberglass structural tubing and how it compares to other materials, such as steel and aluminum.

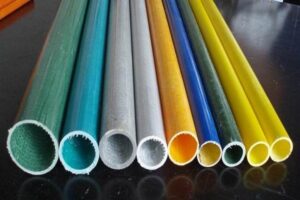

Fiberglass Structural Tubing

What are The Advantages of Fiberglass Structural Tubing:

- High Strength to Weight Ratio: It is much lighter than steel and aluminum, making it easier to handle and transport. This is especially beneficial on large construction projects, where the weight of the material can significantly affect the overall cost and feasibility of the project. Additionally, the fiberglass structural tube has a high strength-to-weight ratio, which means it can support high loads while still maintaining a lightweight construction.

- Corrosion Resistance: It is resistant to rust and other forms of corrosion, making it a suitable material for use in marine and coastal environments. This is especially beneficial for projects in areas where materials are exposed to salt water or other corrosive elements. In contrast, steel and aluminum are prone to corrosion, which can greatly shorten their service life and require regular maintenance and repairs.

- Extremely durable: can withstand extreme temperatures and conditions. It has a high melting point and resistance to UV radiation, making it suitable for use in hot and sunny climates. It is also resistant to impact and bending, making it ideal for structural support in applications where the material may be subject to vibration or movement.

- Excellent Electrical and Thermal Insulation Properties: It is a non-conductive material, meaning it does not conduct electricity, making it a safe choice for use in electrical systems. It also has low thermal conductivity, which means it does not transfer heat easily, making it a good choice for use in insulation or temperature control systems.

- Eco-friendly: it is made from natural materials such as sand and recycled glass, and can be recycled at the end of its lifespan. This makes it a more sustainable option compared to materials such as steel and aluminum which require a lot of energy and resources to manufacture and process.

Overall, fiberglass structural tubing offers a range of advantages over other materials, such as steel and aluminum. Its strength-to-weight ratio, corrosion resistance, durability, and insulation properties make it a highly versatile and reliable material for a wide range of applications. Its environmental benefits also make it an attractive choice for those looking to reduce their carbon footprint.

info@unicomposite.com

info@unicomposite.com