FRP materials have had a major impact on many industries, from construction to wastewater treatment to theme parks. But what advantages does it have over more traditional materials like steel, aluminum, and wood? Read on to find out!

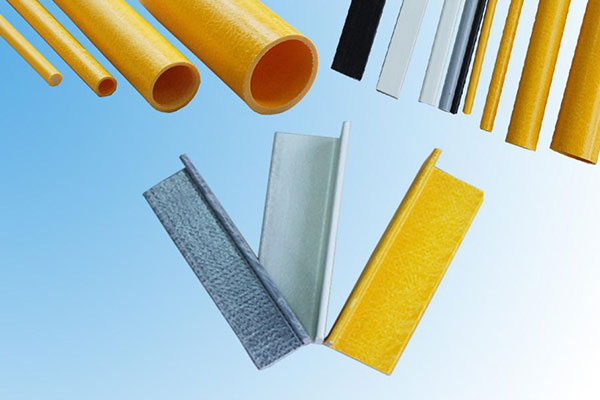

Products made with FRP material

1. Manufacturing and Design

The material has considerable flexibility in design. FRP can be cut on-site using simple carpenter tools such as a cutter. No soldering is required. The material is lightweight and easy to transport and install. In contrast, steel usually requires special equipment to install.

2. Elasticity

Fiberglass products have a hard surface. Coatings covering and tinting finished fiberglass products can be customized to provide greater stiffness or greater elasticity.

3. Cost

While the initial material cost of stainless steel is lower than that of fiber-reinforced plastic, FRP is less expensive to install and maintain, which can reduce overall life cycle costs. Wood is cheaper, but also degrades more easily, resulting in higher maintenance costs. The price of aluminum is comparable to that of fiberglass polymers.

4. Stiffness

FRP is 3.3 times stiffer than wood and does not permanently deform under a working load.

5. Impact Resistance

Fiberglass does not permanently deform or break under impact like traditional building materials. Even at sub-zero temperatures, the glass mats in pultruded parts spread the impact load to prevent surface damage.

6. Resistant to corrosion, rot, and insects

FRP is resistant to many chemicals and is not affected by moisture or immersion in water, making it ideal for protective coverings on surfaces where chemical spills may occur. It is also resistant to insect damage. Steel and aluminum are prone to oxidation and corrosion. For many applications, they need to be painted or galvanized. Even concrete can be damaged by water. Wood warps, rots, and rots when exposed to moisture, water, and chemicals. Wood is also vulnerable to insects such as termites and marine borers.

7. Strength

Fiber-reinforced plastics have greater flexural strength than wood and are generally stronger than steel and aluminum in tensile strength.

8. Weight

The weight of FRP is only 2/3 of aluminum and 1/4 of steel. This makes it easier to lift materials for installation or repair, reducing maintenance and installation costs.

9. Color

Available in a variety of colors.

10. Thermal performance

FRP has low thermal conductivity. Unlike metals such as steel and aluminum, which conduct heat, fiberglass products maintain a constant temperature and are always cool to the touch. Thermal conductivity is 4 BTU in./(hr ft 2 °F) and the coefficient of expansion is 7-8 (in./in./°F)10 -6. The heat and corrosion resistance of FRP makes it successful even in wet, swampy conditions.

11. Insulation

Fiberglass is non-conductive and has a high dielectric capacity, while metals like steel and aluminum are conductive and must be grounded. Even wood conducts electricity when wet.

info@unicomposite.com

info@unicomposite.com