What Are Electrical substations?

Electrical substations are critical components in the transmission and distribution of electricity. They are used to step down high-voltage electricity to lower levels that can be safely distributed to homes and businesses. These substations are often located in remote or harsh environments and must be able to withstand extreme temperatures, high winds, and other natural elements. For this reason, it is important to choose materials that are durable and able to withstand these conditions. Fiber-reinforced plastic (FRP) is one example of an increasingly popular material for substation products.

Electrical Substations

What is FRP?

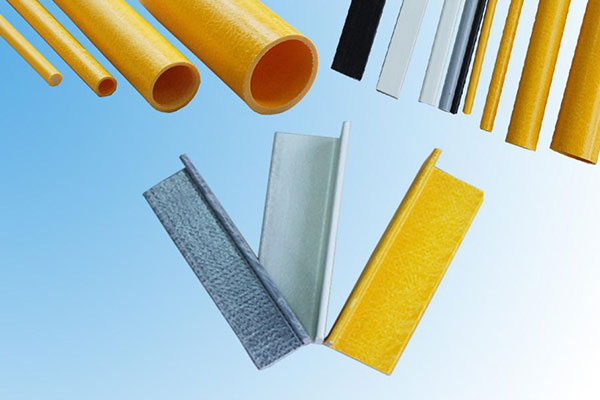

FRP is a composite material made from a combination of fibers and a polymer matrix. The fibers provide strength and stability, while the polymer matrix binds the fibers together and gives the material its shape.

Products made with FRP material

There are many benefits to choosing FRP products for use in electrical substations:

- Durability: FRP is resistant to corrosion, a major concern in substations due to the presence of moisture and other environmental factors. This means that FRP products last longer and require less maintenance than traditional materials such as steel or aluminum. This can save substation operators a lot of money in the long run.

- Lightweight: This makes it easier to transport and install than heavier materials. This also saves installation costs for substation operators.

- Non-conductive: This is an important safety feature for substations where electrical equipment is used. This means there is less risk of electric shock or other accidents when using FRP.

- Fire resistant: this is one of the main concerns of substations. This means that FRP products can help prevent the spread of fire and minimize fire damage.

- Versatile material: can be used in various applications in substations. For example, it can be used to make electrical equipment such as enclosures, insulators, cable trays, and even switchgear. This means substation operators can use one material for multiple applications, saving time and money.

In conclusion, fiber-reinforced plastic (FRP) products are an excellent choice for use in electrical substations. They are durable, lightweight, non-conductive, fire-resistant, and versatile. These benefits can save substation operators money on maintenance and installation costs, as well as improve safety for workers and the surrounding community. As technology for FRP products continues to advance, it is likely that more and more substations will turn to this material as a reliable and cost-effective solution.

info@unicomposite.com

info@unicomposite.com