What is fiberglass?

Fiberglass is definitely the older of the two materials. It is made by extruding it at high temperatures and under high pressure and then combining the resulting strands of material with epoxy resin to make a so-called fiber-reinforced composite (FRP).

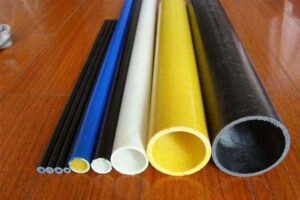

Fiberglass tubes

What is carbon fiber?

Carbon fibers are made up of long chains of carbon atoms bonded together. Thousands of fibers are then combined into tows (also known as bundled fiber tows). These tows can be woven together to form a fabric or laid flat to form a “unidirectional” material. At this stage, it is combined with epoxy to make everything from tubes and slabs to race cars and satellites.

Carbon fiber tubes

Interestingly, virgin fiberglass and carbon fiber exhibit similar handling properties, and if you have black-dyed fiberglass, they also look similar. It’s not until after manufacturing that you start to see the difference between the two materials: namely strength, stiffness, and a small amount of weight (carbon fiber is slightly lighter than glass fiber). As for whether one is better than the other, the answer is “no”. Both materials have their advantages and disadvantages, depending on the application.

Fiberglass Tube VS Carbon Fiber Tube: Which Is Better?

Rigidity

Fiberglass tends to be more flexible than carbon fiber and less expensive. For applications that do not require maximum stiffness – such as storage tanks, building insulation, protective helmets, and body panels – fiberglass is the material of choice. Fiberglass is also often used in high-volume applications where low unit cost is a priority.

Strength

Carbon fiber really shines when it comes to tensile strength. As a virgin fiber, it is only slightly stronger than fiberglass but becomes very strong when combined with the right epoxy. In fact, carbon fiber is stronger than many metals if made the right way. That’s why manufacturers of everything from airplanes to boats are using carbon fiber instead of metal and fiberglass alternatives. Carbon fiber allows for greater tensile strength at a lower weight.

Durability

Where durability is defined as “toughness,” fiberglass is the clear winner. While all thermoplastic materials are relatively tough, the ability of glass fibers to withstand higher pressures is directly related to their flexibility. Carbon fiber is certainly stiffer than fiberglass, but this rigidity also means it’s less durable.

Price

The market for both carbon fiber and fiberglass tubes and sheets has grown dramatically over the years. However, fiberglass materials have a wider range of applications and lower prices.

The reason for the price difference is mainly that manufacturing carbon fiber is a difficult and time-consuming process. By contrast, it is relatively easy to extrude molten glass to form glass fibers. As with anything else, the more difficult the process, the more expensive it is.

At the end of the day, fiberglass tubes are neither good nor bad compared to carbon fiber tubes. Both products have their superior applications, and just choose the right material according to your needs.

info@unicomposite.com

info@unicomposite.com