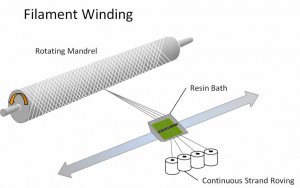

Principle of winding forming method

Filament winding process is one of the main manufacturing processes of resin matrix composites. It is a kind of composite material forming method that under the condition of controlling tension and predetermined line type, continuous fiber or cloth tape is continuously, evenly and regularly wound on the core mold or inner lining after being impregnated with resin glue liquid by special winding equipment, and then it is solidified under certain temperature environment to become a product of certain shape.

Forming equipment

Filament winding machine is the main equipment of filament winding technology. The design and performance of filament winding products should be realized by the winding machine. According to the control form, the winding machine can be divided into mechanical winding machine, digital control winding machine, microcomputer control winding machine and computer numerical control winding machine, which are actually four stages of the development of winding machine. The most commonly used are mechanical and CNC winding machines. Filament winding machine is the main equipment of filament winding process, which is usually composed of fuselage, transmission system and control system. The auxiliary equipment includes glue dipping device, tension measurement and control system, yarn frame, core mold heater, pre-dipped yarn heater and curing equipment, etc.

info@unicomposite.com

info@unicomposite.com