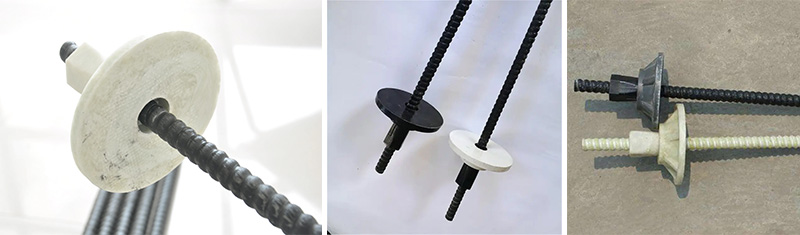

FRP bolts have the characteristics of a light body, strong corrosion resistance, easy operation, high strength, and large anchoring force. They are suitable for rock dust reinforcement with water, acid, and alkali, and are also suitable for flammable and explosive places. Coal mine roadway and underground works such as mines and railways, bolt support of tunnels, bolt support of slopes such as railways and highways, and also used for the support of wharves, etc.

So what should be paid attention to when using FRP bolts?

- Before installing FRP bolts, check the quality of the bolts, whether there are cracks, broken wires, etc;

- The thread at the tail of the FRP bolts rod should be intact and flawless. If there is excess resin, a file should be used to correct the thread;

- The matching tray nut should also not have defects such as cracks;

- Before use, the operator must be familiar with the use method of the bolter and the installation method of the bolt before use.

The next step is to install:

- Use the rock bolt drill to drill holes. After completion, take out the drill rod and push the anchoring agent into the hole with the rock bolt;

- Screw on the FRP tray and nuts;

- Screw the anchor aid to the tail of the bolt, then insert the bayonet of the anchor aid into the drill pipe link sleeve of the bolt drilling rig, and drill the anchoring agent into the bolt hole;

- Use the top of the anchor rod to stand against the anchoring agent. At this time, start the propelling leg of the anchor rod drilling rig to make an upward movement, and the motor of the drilling rig does not rotate and push the anchoring agent into the bottom of the hole;

- Start the motor drilling rig to rotate, the anchor rod rises while rotating and stirring the anchoring agent. When the glass fiber reinforced plastic anchor rod reaches the bottom of the hole, the drilling rig stops rising. The drilling rig rapidly rotates and stirs the anchoring agent. The stirring time is generally 10-15s, that is, close the drilling rig and wait for the anchoring agent After curing, unscrew the anchor rod installer and lower the drilling rig at the same time, and the anchor rod installation is completed.

Pay attention:

- Before installing the bolt, the stability of the roof and the coal gang must be ensured for safe operation;

- When installing the anchor rod, it is not allowed to hold the anchor rod by hand to avoid accidents;

- When the bolt is installed, do not put your hand on the air leg when the rig falls back to prevent hand injury.

info@unicomposite.com

info@unicomposite.com