After several years of development, polyurethane pultrusion has been commercialized. In the polyurethane pultrusion process, more reinforcing fibers can be used to greatly increase the strength of the product. At the same time, due to the excellent impact strength, tensile strength and interlayer shear strength of polyurethane itself, the products can be made thinner and lighter. For example, a thinner I-beam can be made with less continuous raw silk felt and more untwisted roving, reducing the thickness of the I-beam from 3.3mm to 2.6mm, while maintaining its longitudinal rigidity. In this way, the product is reduced by 13% in weight and 7% in cost. In addition, because the pultruded polyurethane product is less brittle, it can be assembled in a conventional manner without cracking and breaking.

The main advantages of glass fiber reinforced polyurethane pultruded composites are embodied in the following aspects:

- The fiber content is high, and the weight content can easily reach more than 80%. The fiber structure is simple and the profile performance is superior, which reduces or even eliminates the use of fiber felt or cloth, greatly simplifies production and improves efficiency.

- It can produce profiles with complex cross-sections and thin walls without cracking.

- The surface of the profile is smooth, and the material performance and quality are stable and reliable.

- Closed mold production process: closed loop mixing and infiltration. The proportioning, conveying, mixing and soaking of the resin are carried out in a closed pipeline without contact with the environment, which not only avoids the influence of dust and moisture in the environment on the product.

- Clean and environmentally friendly production: Polyurethane resin does not contain styrene, and there is no pungent odor in the production site, which minimizes the impact on the environment and the health of workers.

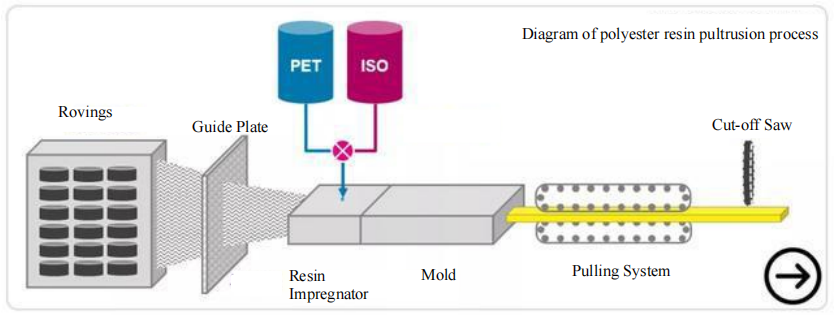

- Fully automated production. All processes such as raw material proportioning, mixing, conveying, fiber infiltration, traction, profile curing and forming, and cutting are completed by automatically controlled equipment to ensure the consistency of product quality.

polyurethane pultrusion

info@unicomposite.com

info@unicomposite.com