Polyurethane pultruded products include various rods, flat plates, hollow tubes and profiles, which are widely used in the market.

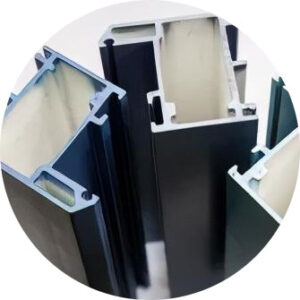

1. Door and window profiles

High heat insulation: Polyurethane pultruded composite profile has a very low thermal conductivity like solid wood and PVC, 0.34 W/m•K at room temperature, only about 1/700 of aluminum alloy, and is an excellent thermal insulation material.

Low thermal expansion: The linear thermal expansion coefficient of polyurethane pultruded composite profile is about 7×10-6/K, which is much lower than that of aluminum alloy, and is similar to the linear thermal expansion coefficient of the wall; therefore, when the temperature changes, the polyurethane pultruded composite profile The frame body will not have a gap with the wall body, and the airtightness is good, and at the same time, the heat insulation of the whole window is ensured in an environment with a large temperature difference.

Corrosion resistance: Polyurethane pultruded composite profiles have strong corrosion resistance to most acids, alkalis, salts, organics, as well as sea water and humid air; and they are not rusty and immortal, and their corrosion resistance is better than other door and window profiles. Especially suitable for coastal, corrosive and general humid places.

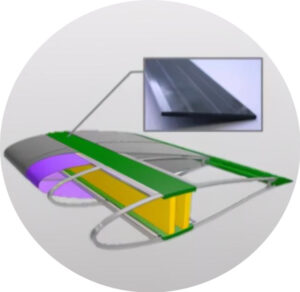

2. Main beam of wind turbine blade

The main advantages of using pultruded sheet to make the blade beam are reflected in the following aspects:

· Mechanical properties

· Compared with vacuum infusion process, pultrusion has more advantages in industrial production

· High glass fiber content

· Fibers are arranged more evenly in the composite material

· Reduce risk factors in the production process

· The pultruded sheet can be pre-inspected before entering the mold to minimize defects

· The pultrusion process can minimize the influence and interference of human factors

· Shorten the occupying time

3. Cable tray

Historically, unsaturated polyester has been used more often, but now it has basically switched to polyurethane pultrusion. Polyurethane pultrusion bridge frame has advantages in terms of the convenience of on-site construction and the service life;

Polyurethane bridge has high tensile properties, impact resistance and corrosion resistance. Compared with unsaturated polyester resin, polyurethane improves the physical properties, strength and rigidity of the product in an all-round way.

Fast pultrusion speed and high production efficiency.

Polyurethane products have excellent toughness, the processed and punched edges show little or no microcracks, the surface is fine and smooth, the rigidity is strong, and the porosity is low, which is conducive to subsequent processing such as drilling, machining and assembly operations .

Solvent-free styrene (toxic chemicals), no solvent volatilization during the production process, and no styrene emissions.

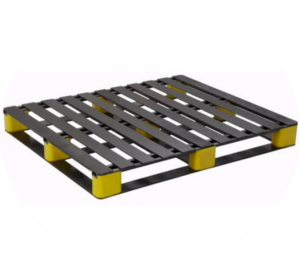

4. Pallet

Due to the toughness of polyurethane composite material, its impact resistance and shear strength are much higher than traditional materials, and the service life of pallets can be 20 times more durable than traditional wooden pallets. Polyurethane pultruded trays have long cycle life, low cost per cycle, and good economic benefits.

5. Container floor

Compared with traditional wood-based materials, the use of polyurethane pultrusion technology will reduce the weight by 22%, reducing the fuel consumption and transportation costs of the entire ship and container. While being lightweight, it also maintains sufficient toughness. This feature also reduces maintenance costs and increases the service life of the container. The service life of traditional container wood flooring is only 5-10 years, while the service life of polyurethane pultruded flooring can exceed 20 years. Its special properties are:

· Low weight, which can reduce energy consumption during transportation

· Strong durability (water, oil, odor, microorganisms)

· Increase the service life of containers

· Reusable and recyclable flooring

6. Other uses

Polyurethane pultruded products include profiles, rods and plates, such as ladder poles, tool handles, telegraph poles, electric poles, hockey poles, pier piles, container plates, etc.

info@unicomposite.com

info@unicomposite.com