In traditional swimming pool construction, steel rebars are used as bars in concrete. Before pouring the concrete, the length of the steel bars are crossed longitudinally in the pool from side to side and installed in a grid. Steel rebar is functionally efficient and relatively cheap, so it does the job well in most cases. However, steel rebars have their own weaknesses: they are easily corroded (oxidized) and conductive when exposed to salt, corrosive chemicals, and moisture. As the steel rebar corrodes, the steel rebar expands and increases the tensile load on the concrete, which starts to produce cracks and spalling, forming openings, causing the steel rebar and concrete to further deteriorate faster. This requires expensive repairs and maintenance, and if allowed to go far enough, it will compromise the integrity of the structure.

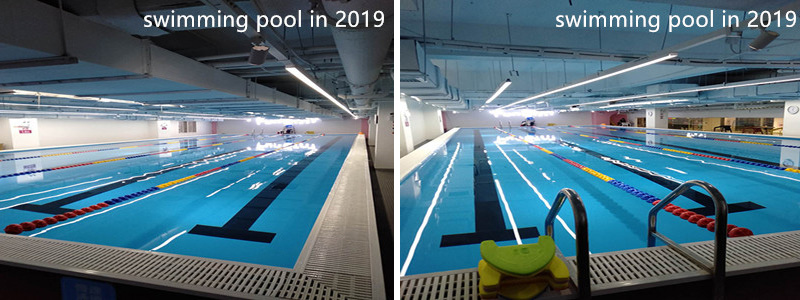

This is the swimming pool of a fitness club in Nanjing, the project used Unicomposite’s FRP rebar.

FRP rebar is a kind of composite rebar, used to replace corroded classic steel rebar. Unicomposite’s FRP rebar is made of high-strength glass fiber and very durable vinyl ester or epoxy resin. The fiber enhances the strength of the rod, while the vinyl ester or epoxy resin imparts excellent corrosion resistance under harsh chemical and alkaline environments; in order to improve stiffness and mechanical properties, glass fiber and epoxy resin are also provided High modulus. It has higher strength than steel and lighter, and has been tested and approved. It can be used in many fields, such as concrete roads, bridge decks, bridge curbs, pier covers, sidewalks, barrier walls, sound barriers, airport taxiways, water supply systems and pipes The ideal solution for treatment plants, breakwaters, docks and installations, ports, parking garages, saltworks, swimming pools, industrial areas, seawater desalination entrances, etc.

The swimming pool construction contains hundreds of FRP rebars. First make a grid in the vertical and horizontal directions, and then encapsulate it in concrete.

Features and advantages of FRP rebars:

- High strength/weight ratio: provides good reinforcement in weight-sensitive applications.

- Non-corrosive: will not corrode when exposed to a variety of corrosive elements including chloride ions.

- Non-conductive: provides excellent electrical and thermal insulation.

- Excellent fatigue resistance: excellent performance under cyclic loading.

- Good impact resistance: resistance to sudden and severe point loads.

- Electromagnetic transparency: not affected by electromagnetic fields.

- Lightweight: easy to transport and assemble on site without heavy lifting equipment.

info@unicomposite.com

info@unicomposite.com