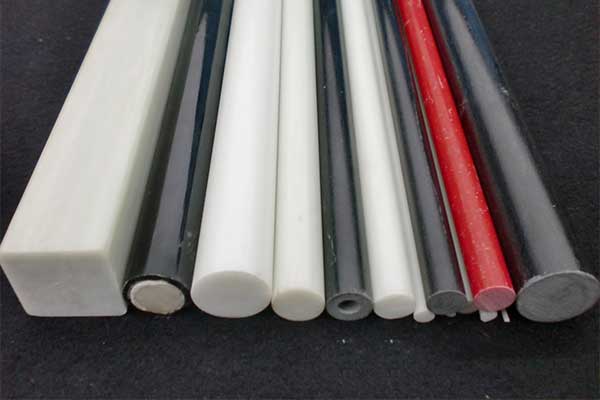

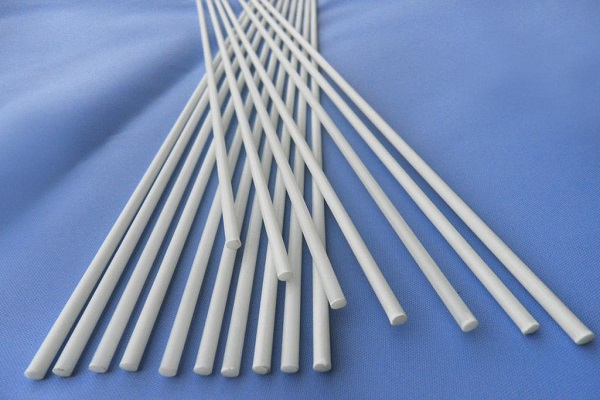

Pultruded fiberglass rod from Unicomposite is a type of composite material made of glass fibers that are pulled through a resin bath and heated to cure. The resulting rod has high strength, good corrosion resistance, and low thermal expansion. It is used in various applications, including electrical insulators, reinforcement in construction, and support structures in many industrial applications.

Pultruded Fiberglass Rod Product Highlights

| Process Used | Pultrusion |

| Material Used | Unsaturated Polyester, Vinyl Ester, Epoxy, Etc |

| Product Dimensions | Product Length: 1 to 2,000 feet Material Thickness: 1/8″, 3/16″, 1/4″, 5/16″, 1/8″, 3/8″, 5/8″, 7/8″, etc diameters |

| Colors | White, Black (Colors can be changed according to customer requirements) |

| Standards | Customer Specifications |

| Services | OEM & ODM |

Features of Pultruded Fiberglass Rod

- High Tensile Strength

- High Corrosion Resistance

- Lightweight

- Electrically Insulative

- Customization

- Cost-effective

Some common uses for pultruded fiberglass rods include:

- Structural Support

- Antenna Masts

- Electric Utility Poles

- Fiber Optic Cable Support

- Handrail And Guardrail Systems

- Plant Stakes

- Fishing Rod

- Medical Equipment

FAQ

What is Pultruded Fiberglass?

Pultruded fiberglass is a type of composite material made by pulling fibers through a resin matrix. The fibers provide strength and stiffness, while the resin binds the fibers together and protects them from the environment.

Are Fiberglass Rods Bendable?

Yes, fiberglass rods can be bent, but they have a limited degree of flexibility and can break if bent too far or at the wrong location. The bendability of fiberglass rods depends on factors such as the diameter, modulus of elasticity, and the manufacturing process.

Which is Stronger Graphite or Fiberglass?

Fiberglass is stronger than graphite in terms of tensile strength, meaning it can withstand a greater amount of force before breaking. However, graphite is typically lighter and has better flexural strength, meaning it is less likely to break under bending. It also has better thermal and electrical conductivity. The strength and suitability of either material for a specific application depend on the required properties and the intended use.

Can Fiberglass Be as Strong as Metal?

Fiberglass can have comparable strength to metal in certain applications, depending on factors such as the type of fiberglass and the way it’s fabricated. For example, fiberglass-reinforced plastic (FRP) can be as strong as steel in tension, but not as strong in compression. However, it is more resistant to corrosion, lighter in weight, and has better thermal and electrical insulation properties than metal. The choice between fiberglass and metal depends on the specific requirements of each project and should be evaluated based on trade-offs between strength, weight, cost, and other factors.

What is Pultrusion Used for?

Pultrusion is a manufacturing process used to produce fiber-reinforced polymer composites (FRP) with constant cross-sectional profiles. The process involves pulling a mixture of reinforcement fibers (such as glass or carbon fibers) and resin through a heated die, where the resin is cured and the composite is formed. The resulting parts are strong, lightweight, and corrosion-resistant, making them suitable for a range of applications, including construction (e.g. decking, handrails, structural shapes), transportation (e.g. truck bodies, trailers), electrical (e.g. poles, conduit), and recreational products (e.g. fishing rods, golf clubs).

info@unicomposite.com

info@unicomposite.com