The application range of fiberglass(FRP) grating is very wide. Due to its strong plasticity, high safety, and bright color, it has received extensive attention from friends from all walks of life. Among the many advantages of FRP grating, due to its excellent corrosion resistance and aging resistance, it can be used in some harsh environments, and it is widely used in electroplating plants, sewage treatment plants, and factories.

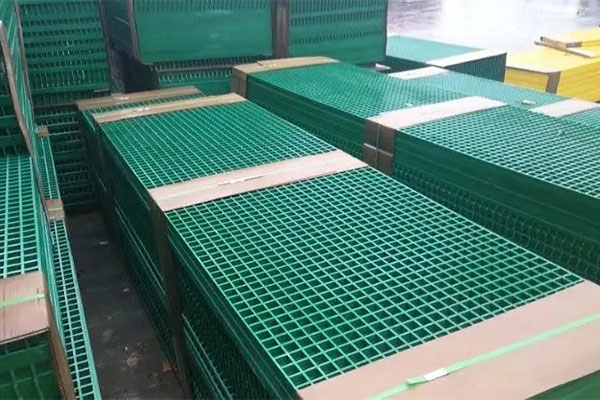

Fiberglass walkway grating

The advantages of using fiberglass grating walkways:

In terms of installation, it is very convenient to use FRP grating as a channel. Compared with the previous products, the FRP grating is lighter in weight, does not require the use of special lifting equipment, reduces the installation cost, and makes the installation work easier due to its plasticity and perfect structure.

In traditional projects, the guardrails and aisle slabs of sewage treatment tanks are made of metal materials. In daily work, the water splashed by the treated sewage is highly corrosive. Or the water vapor volatilized in the air has a strong corrosive effect on metal materials. In the long run, metal parts will rust or even be damaged, and there is a great hidden danger in safety.

The fiberglass grating walkway is mainly made of unsaturated polyester resin (including isophthalic acid type, ophthalmic type, vinyl type, and phenolic bisphenol A type), and glass fiber roving is used as reinforcement material. FRP grating walkways will not rust, corrode, not corroded by water molecules in the air, and do not require special maintenance inspections, which can bring great convenience to users.

As a new type of composite material, the FRP grating walkway has a special manufacturing process, which provides a safety guarantee for users. During use and installation, FRP grating will not generate sparks due to accidental collisions, so it can be used in some flammable and explosive environments. For example, when used in electric ‘petroleum’ electroplating plants, safety can be said. Many have improved. Its surface anti-skid design can play a good anti-skid effect even in a humid environment, reducing the occurrence of safety accidents.

info@unicomposite.com

info@unicomposite.com