FRP is also known as GFRP, namely fiber reinforced plastics, generally used to enhance unsaturated polyester, epoxy resin and phenolic resin matrix with glass fiber.

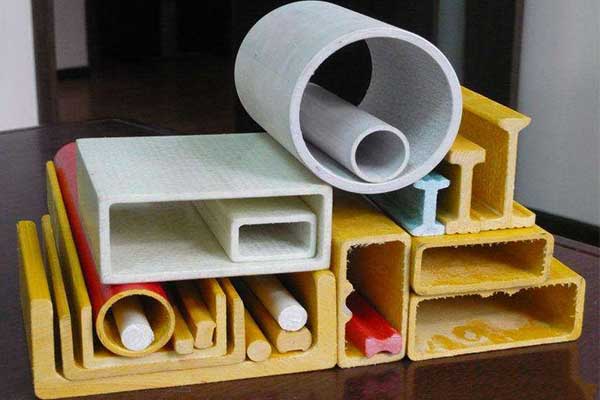

Various fiberglass products

These made with Reinforced plastic or its products is called fiberglass reinforced plastic, or called fiberglass, please note to distinguish it from tempered glass. Because of the different resin varieties used, it is known as polyester FRP, epoxy FRP and phenolic FRP. It is Light,hard and non – conducting, at the mean time with stable performance, high mechanical strength, less recycling and corrosion resistance, which can replace steel machine parts, cars, ship shells, etc.

| Glass Profile | Carbon Profile | Steel | Aluminium | PVC | Wood |

Density(kg/m3) | 2100 | 1650 | 7900 | 2700 | 1380 | 520 |

Flexural strength (MPa) | 1000-1400 | 1400-2500 | 400-1200 | 180 | 44 | 150 |

Flexural modulus (GPa) | 45-56 | 120-300 | 196 | 70 | 2,4 | 10 |

Tensile strength(MPa) | 1000-1400 | 1400 | 400-1200 | 180 | 70 | 100 |

Tensile modulus (GPa) | 45 | 140 | 196 | 70 | 2,4 | 9 |

Thermal conductivity (W/m.K) | 0,5 | 1,4 | 47 | 209 | 0,24 | 0,47 |

Coefficient of linear thermal expansion (1/K) | 10-5 | -0,2.10-6 | 10-5 | 2,3.10-5 | 3,7.10-5 | 0,2.10-5 |

Specific heat capacity (J/kg.K) | 1880 | 950 | 461 | 921 | 1100 | 1700 |

Fiberglass Products Advantage characteristics

1. Good corrosion resistance

FRP is a kind of composite material, which is good corrosion resistance, oxidation of the atmosphere and water and general concentration of acid and alkali salt and so on the many kinds of solvent has strong resistance ability, all aspects have been applied to environmental protection, chemical corrosion, it will replace carbon steel, stainless steel, wood, non-ferrous metal and so on gradually.

2. Light weight, high strength

The relative density is between 1.5~ 2.0, only 1/4-1/5 of carbon steel, but the tensile strength is close to or even more than carbon steel, compared with the strength of the high alloy steel.

Therefore, in aviation, rockets, space vehicles, high pressure vessels and in other products that need to reduce weight, they have excellent results. The tensile, bending and compression strength of certain epoxy FRP can reach over 400Mpa.

3. Good insulation performance

It is a fine insulating material which used to make an insulator. High frequency can still protect good dielectric. Microwave transmission is good and has been widely used in radar radome.

4. Good thermal conductivity

The FRP thermal conductivity is low to be 1.25~1.67 kJ/(m •h• K) at room temperature, which is only 1/100~1/1000 of the metal, it is an excellent insulator. Under the condition of the instantaneous ultra high temperature, it is the ideal thermal protection and ablation resistant material, can protect the spacecraft at above 2000 ℃ under high-speed air flow.

5. Strong design

a. It can be flexible to design various structural fiberglass products to meet the requirements of application and it has good integrity.

b. The materials can be fully selected to meet the performance of the products, such as: it can be designed for corrosion resistance, instantaneous high temperature, special high strength in the direction of products, good dielectric, etc.

6. Good technology

a. Unicomposite can choose the forming process flexibly according to the shape, technical requirements, use and quantity of the products.

b. The process is simple and can be formed at a time. The economic results are outstanding, especially for the products with a small number of complex shapes and not easy to form, and the advantages of the technology are highlighted.

info@unicomposite.com

info@unicomposite.com