After the FRP grating is manufactured, there are usually several different surface: Concave Surface, Sanded Surface, Smooth Surface and Covered with Solid Top.

How to deal with the FRP grating needs to be determined according to the specific situation. If a non-slip treatment is required, the concave surface and sanded surface can be choosed. If you don’t need a non-slip finish, you can sand it to make it look smooth and flat. If there is a requirement for air tightness, you can choose the surface with solid top.

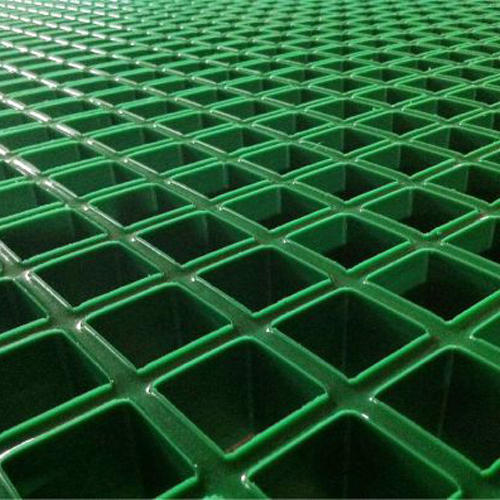

- concave

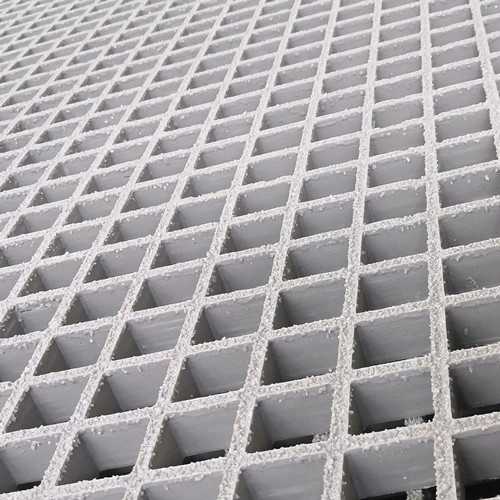

- concave sanded

- smooth

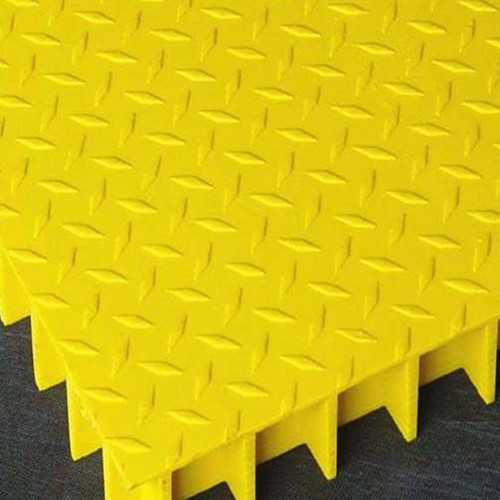

- FRP grating cover

Concave Surface

When making FRP grating, manual extrusion is required, so one side of the finished FRP grating is flat (that is the bottom surface), and the other side is a crescent shape formed by extrusion. When fiberglass reinforced plastic gratings are typically used as artificial walkways, no treatment is required. The crescent surface itself is a very good anti-slip measure.

Sanded Surface

Generally, customers need to book in advance when they need a sand-surface FRP grating, because the finished FRP grating is no longer can be sanded, but sanded during the production process.

Smooth Surface

FRP grating with smooth surface is generally used in some occasions that do not require manual or machine walking, such as FRP grating ceiling, FRP grating operating platform, FRP grating guardrail, FRP grating wall, etc. Because in these occasions, the overall beauty is necessary, so the FRP grating will be processed by a grinding machine to make a double-plane grating plate.

Solid Top Surface

FRP grating with solid top is designed for loading and storage areas with high foot and cart traffic. The fiberglass covered grating panel has one solid fiberglass plate attached to the top surface, which offers strong, level surface and higher stiffness values than that of open mesh gratings. The covered grating is stiffer than common open mesh gratings, and the decorative pattern adds beauty to the grating.

Compared with the concave-surface FRP grating, the sand-surface FRP grating is more wear-resistant, and the anti-slip effect of the concave-surface FRP grating is only suitable for artificial walkways. If the automobile machinery equipment large weight, etc., the choice of sand-surface FRP grating is more suitable. Once the concave surface is ground, it loses its anti-skid function, while the frosted FRP grating is different, the sand added during production is deeply embedded in the grating plate, which has a good anti-slip effect.

The above is an introduction to the various panel surfaces of the anti-skid FRP grating.

info@unicomposite.com

info@unicomposite.com