FRP grating often needs to be adjusted differently for different environments during installation. The style of the grating used for replacing a grating plate is different from that used for full-page installation. At this time, it is necessary to cut the periphery of the grating plate to match the surrounding. The following introduces several conventional cutting methods of FRP grating.

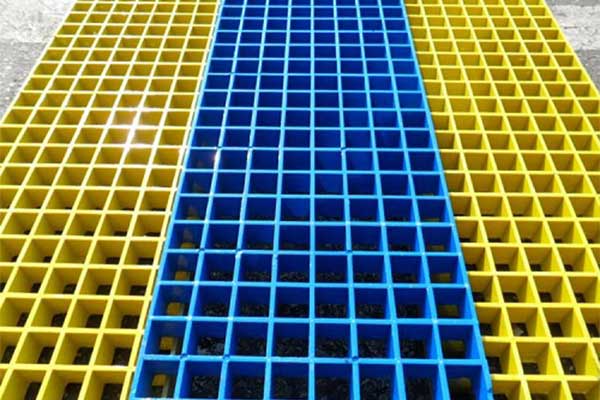

FRP grating

The cutting of FRP grating should be cut after the production of the full-page FRP grating. Manual cutting requires the cutting personnel to control the cutting machine more accurately; large-scale cutting machines have small errors that need to be fixed before cutting. Generally, when cutting, it is 2mm-5mm smaller than the installation size required by the customer, which is convenient to leave space for installing the grille plate.

FRP grating Cutting tool selection:

- Straight line cutting: FRP grating can be cut on-site using mechanical cutting methods such as ceramic disc or emery disc cutter, or even ordinary hacksaw blades, but it is not recommended.

- Curved cutting: Grid openings, arcs, and other arcs can be cut with an electric saw or hacksaw equipped with a metal cutting blade.

- Grinding: It can be polished with a portable angle grinder, a grinder, a common file, and sandpaper.

- Drilling: Holes above 12mm can be drilled with a common drilling machine twist drill, and small holes can be drilled with a hand-held electric hole processing machine or a general flashlight.

FRP grating Cutting tool

FRP grating conventional cutting method:

Type A: Surrounding edge (optional tooth edge)

Beautiful and neat, but the cost is relatively high, the grid wrapping, the length and width dimensions must meet: N (the number of grids) * single grid size (such as 38.1) + grid width (such as 7) mm. It is mostly used for full-page laying in car washrooms.

Type B: Hemming on the opposite side

Neat and relatively high cost, one set of opposite sides should meet the A-type size requirements, and the other set of opposite sides is symmetrically cut.

Type C: Three loaf sides

It is neat and relatively beautiful after paving and is often used in trenches and walkways.

Type D: splicing cutting method

Economical methods, such as full edging, no edging, and partial edging may exist at the same time, which is relatively messy after paving, and is generally not recommended.

info@unicomposite.com

info@unicomposite.com