FRP rebar is a composite material made of high-strength glass fiber as a reinforcing material, synthetic resin as a matrix material, and an appropriate amount of auxiliary agents. It is called glass fiber reinforced plastic (English abbreviation FRP). Commonly used fiberglass rebar in the market is diameter from Φ3mm~Φ36mm.

Glass fiber: also known as alkali-resistant glass fiber, alkali-resistant fiberglass roving is the rib material of glass fiber reinforced (cement) concrete (GRC). It is 100% inorganic fiber. It is ideal alternative to steel and asbestos in non-load-bearing cement components. Alkali-resistant glass fiber is characterized by good alkali resistance, can effectively resist the erosion of high-alkali substances in cement, strong binding force, elastic modulus, impact resistance, tensile strength, high bending strength, and temperature resistance. Strong humidity change ability, excellent crack resistance and impermeability performance, strong designability, easy forming, etc. Alkali-resistant glass fiber is a new type of green and environmentally friendly reinforcement widely used in high-performance reinforced (cement) concrete material.

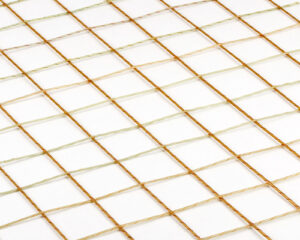

The production process of FRP rebar mesh is different from regular fiberglass rebar, its production process is more complicated, and the size of the mesh is customized according to the specific requirements of the customer. Once it is formed, it cannot be adjusted or modified. Reinforced mesh has many advantages:

- Reinforced rebar mesh has large mesh rigidity, good elasticity, uniform and accurate spacing, and high strength of connection points. Can greatly improve the quality of the project.

- Improve seismic and crack resistance. The longitudinal and transverse rebars of the mesh form a network structure, so it has good adhesion and anchorage with concrete, and the load is evenly spread and distributed, which significantly improves the seismic and crack resistance of reinforced concrete structures.

- The use of rebar mesh can make the construction of the project faster. As long as themesh is laid according to the requirements, the concrete can be poured, no need for on-site cutting, placing one by one, and tying the rebar. It can save 50%-70% of working hours, greatly speed up the construction progress and shorten the construction period.

- unicomposite.com 2021 03 12 07 51 37

- unicomposite.com 2021 03 12 07 51 47

info@unicomposite.com

info@unicomposite.com