Flagpoles can be seen in hotels, campuses and other places. There are many materials for flagpoles, such as stainless steel, aluminum and fiberglass.

The fiberglass that is used for making flagpoles is made up of individual glass fibers and other raw materials. The glass fibers are mixed in with other ingredients and limestone and heated to a high temperature to form a plastic substance.

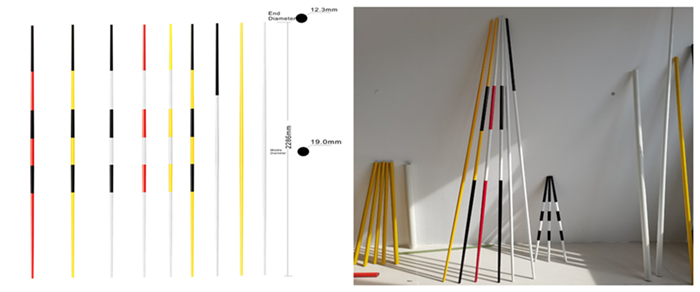

Before enduring the hot mold process, the flagpoles are gel-coated on the inside. This particular molding process ensures that the pole is 97 percent cured when it is removed from the mold, and that the coating will experience minimal evolution over the poles life. The FRP flagpoles can be solid rods or tube, straight or tapered.

Features of fiberglass flagpoles:

- The non-oxidizing surface makes it an excellent choice when close to salt water or in extreme weather conditions

- Maintenance-free, no need to repaint, easy to clean

- Light weight, only 1/4 weight of steel while have similar strength

- Excellent strength, more flexible than aluminum. The tensile strength exceeds 50,000 psi, while the tensile strength of aluminum is 35,000 psi

- Flexible colors, integrity color, not painted

- Non-conductive and no need to be grounded

- UV resistance, moisture-resistant and non-corrosion

info@unicomposite.com

info@unicomposite.com