FRP (molded) grating is a kind of unsaturated polyester resin (including isophthalic, phthalic, and vinyl) as the matrix, with glass fiber yarn (medium alkali or alkali-free) as the skeleton in a custom mold. A board with a certain opening rate is made by a special process.

FRP grating

The main components of FRP grating have resin; glass fiber; filler: aluminum powder (aluminum hydroxide) or calcium powder (fossil powder, quartz powder); color paste; foaming agent, strengthening agent).

FRP grating production process

- Mix the resin, filler, color paste, and trace reagents in a certain proportion and stir together.

- Pour a small amount of the mixture into the grill mold and evenly coat the bottom of the mold.

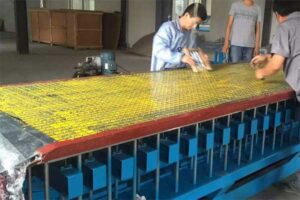

- The yarn is made up of 3 small strands into a large strand, which is threaded into the rower (tool in the hands of the worker), and the rower is used to draw the yarn in the mold. As shown in the picture, the worker is holding a rower with three heads, and each head has a large strand of yarn. Workers draw horizontally and vertically to form a layer. After each 2, 4, 6, and 7 layers, each press the knife once. The purpose of pressing the knife is to incorporate more yarn, and while cutting the yarn, it is necessary to continuously pour the mixed resin, so that the resin and the yarn are fully mixed.

- Heat for a certain period of time, and then come out of the mold, there are many small jack pins under the mold, start the switch, all jack pins together push the grille out, because the grille is 7mm and 5mm lower, and it is inclined, just use a little force The grille can be pushed out.

FRP grating production workshop

FRP grating product structure

- The staggered weaving of glass fibers and the full infiltration of resin makes the grille bear maximum load.

- The overall structure of the FRP grating will distribute the load evenly, which is helpful for the installation of the FRP grating and the design of the supporting structure.

- The glossy surface and italic surface of the FRP grating make the FRP grating self-cleaning.

- The concave surface of the FRP grating makes the grating have anti-skid performance, and the anti-skid effect of the sanded surface is better.

info@unicomposite.com

info@unicomposite.com