What is Pultrusion?

Pultrusion is a manufacturing process that is used to produce fiber-reinforced composites, specifically fiber-reinforced polymer (FRP) composites. The pultrusion process involves pulling fiber reinforcements through a resin bath and then through a heated die where the resin cures and solidifies, forming a composite profile with a constant cross-section. The end result is a composite material with consistent strength, dimensional accuracy, and uniformity. The pultrusion process is commonly used to manufacture FRP composites in various shapes and sizes for a wide range of applications, including construction, transportation, electrical, and renewable energy industries.

What is Pultrusion Machine?

A pultrusion machine is a key component in the pultrusion process. It is a specialized machine that is designed to produce composite profiles with consistent quality and efficiency. The pultrusion machine typically consists of several main components: a resin bath, a puller, a die assembly, and a take-off unit. The resin bath is where the fibers are impregnated with resin, the puller pulls the fibers through the bath and the die, and the die assembly is where the resin cures and solidifies. The take-off unit is where the composite profiles are removed from the die assembly and cooled.

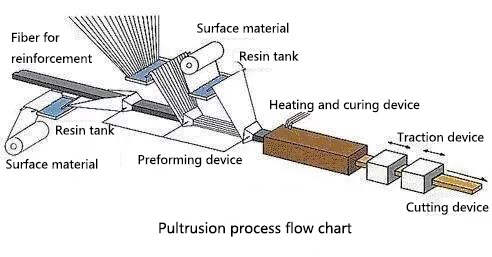

The Working Principle of Pultrusion Process

The pultrusion process begins by loading fiber reinforcements into the resin bath. The fiber reinforcements are typically made of glass, carbon, or aramid fibers, and they are positioned in the bath so that they are thoroughly saturated with resin. The puller then pulls the fibers through the resin bath and the heated die, where the resin cures and solidifies. The take-off unit removes the composite profiles from the die assembly and cools them to the desired temperature.

Advantages of Pultrusion

- High Quality and Precision: It allows manufacturers to produce composite profiles with consistent quality and dimensional accuracy. The pultrusion process ensures that the fibers are evenly distributed and thoroughly saturated with resin, resulting in a composite material with consistent strength and uniformity. In addition, the pultrusion process is highly automated, which makes it possible to produce composite profiles in large quantities with consistent quality and dimensional accuracy.

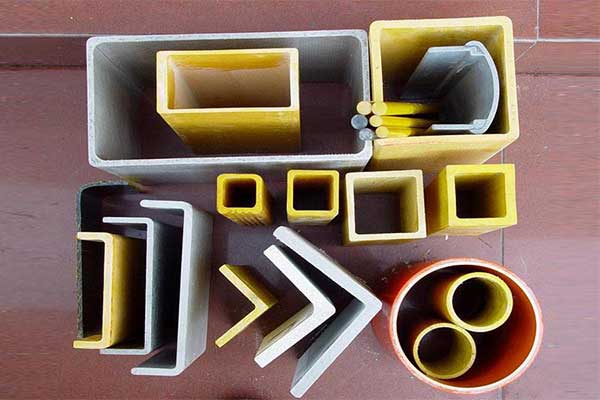

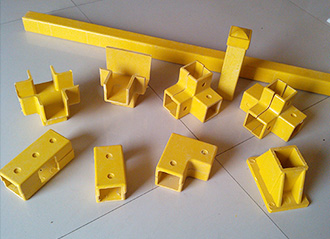

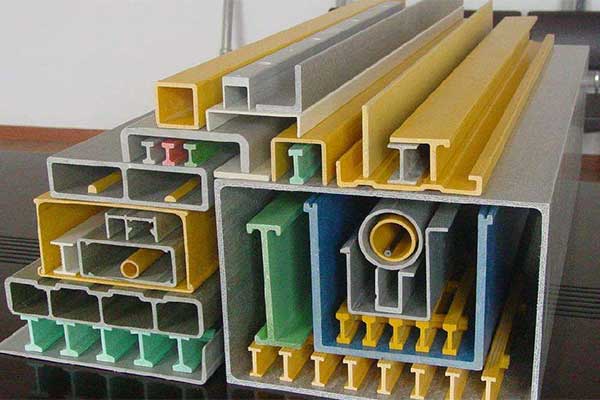

- Customizable: it can produce composite profiles in a wide range of shapes and sizes. The die assembly can be designed to produce composite profiles with a constant cross-section, which makes it possible to produce composite profiles with complex shapes. This is particularly useful for applications where custom shapes are required, such as in the construction industry where pultrusion is used to produce beams, columns, and other structural components.

- Highly Efficient: Making it possible to produce composite profiles in large quantities in a relatively short amount of time. This is particularly useful for applications where high-volume production is required. The high production efficiency of the pultrusion process also makes it possible to produce composite profiles at a lower cost compared to other manufacturing processes, making it an attractive option for manufacturers looking to reduce production costs.

- Environmental Friendly: Pultrusion is a clean and environmentally friendly manufacturing process. Unlike other composite manufacturing processes, pultrusion does not produce waste or pollutants, which makes it an attractive option for manufacturers looking to reduce their environmental impact. The pultrusion process also does not produce harmful emissions, making it a healthy choice for workers and environmental safety.

Pultrusion Machines Are Used in a Wide Range of Industries and Applications

- In the building and construction industry, FRP products produced by pultrusion machines are used for structural components, such as beams, rods, and decks. These products offer a number of benefits over traditional building materials, such as wood, steel, and concrete. They are lightweight, corrosion-resistant, and have a high strength-to-weight ratio, making them ideal for use in high-rise buildings, bridges, and other structures.

- In the transportation industry, pultrusion machines are used to produce FRP components for trains, buses, and boats. These components are lightweight and corrosion-resistant, making them ideal for use in harsh environmental conditions. They are also fire-resistant, providing an added level of safety in the event of an accident.

- Pultrusion machines are also used to produce FRP parts for a variety of sports equipment, including golf clubs, tennis rackets, and bicycles. These parts offer high strength and stiffness, allowing for the production of lightweight and durable sports equipment.

info@unicomposite.com

info@unicomposite.com