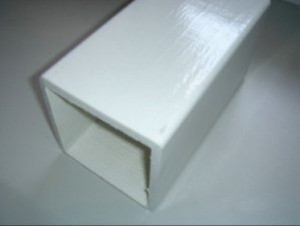

Priming paint

The selection of primer is very important to the coating quality. As a primer, it must have good corrosion resistance, good adhesion to the substrate and good matching with the top coat. Special attention shall be paid to the edges and corners of the primer during spraying. If there is dead angle, it is not easy to spray. The spray coating on these parts is the most likely to thin, so special attention shall be paid. The primer layer must be properly dried before painting. If it is too small, the primer layer is easy to be bitten by some top coats. If it is too dry, it is not well combined with the paint surface, and it is easy to form shrinkage cavity and fermentation. In addition, special attention shall be paid to prevent the primer workpiece from being polluted again after spraying.

Sprayed finish

The finish coat shall be applied after the primer is completely dry. The top coat on FRP items shall be uniform, dense and bright, and completely cover the previous paint layer, generally 2-3 layers. The total thickness of the bottom and top coat shall not be less than 20 microns. Before the paint film is dry, it should be properly protected to avoid all kinds of pollution and direct sun exposure or freezing. After the completion of painting, the painting tools and equipment shall be maintained, the painting far auxiliary materials shall be well maintained, the fire hazards shall be eliminated, and the safety measures shall be implemented.

Paint precautions

The painting site shall be kept clean, well ventilated and free from fire hazards. At the end of the treatment, the workpiece can be sprayed on the surface after being dried and dustproof. For the products that do not need to be painted, the coating shall have good adhesion color to meet the requirements of the drawing. No wrinkles, spots, fine sand grains, bottom marks, pinholes, bubbles, transparent bottom colors, adherents and other defects are allowed on the spray surface of the front and side of the product. The color shall be uniform. In the absence of direct sunlight, visual inspection shall be conducted one meter away from the product, and no brush marks, copy marks, mechanical magazines and finishing marks shall be found. Before spraying the second bar of finish paint, the installation holes or parts with installation coordination requirements must be cleaned to eliminate the possible installation quality caused by the painting procedure. The coating outside the front and side of the product is not allowed to have wrinkles, flow marks, bubbles, transparent color and other defects, but a small amount of mechanical impurities are allowed.

info@unicomposite.com

info@unicomposite.com