What is Pultrusion?

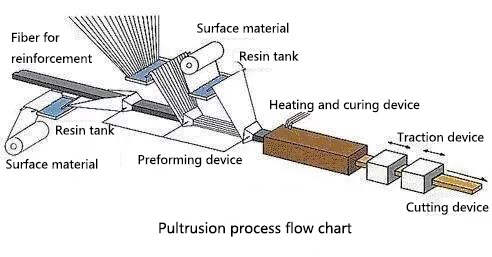

Pultrusion is a manufacturing process that is used to produce composite materials, such as reinforced plastics, with consistent properties and a high degree of strength and dimensional accuracy. The process involves pulling a continuous reinforcement material, such as fiberglass, through a resin bath and then into a die, where the reinforcement and resin are cured under controlled conditions. The result is a composite material with a high strength-to-weight ratio and excellent resistance to impact, corrosion, and other forms of degradation.

What is It Used For?

Pultrusion is used for a wide range of applications, including construction, transportation, and industrial equipment. One of the most common uses of pultruded materials is in the construction industry, where they are used for structural members such as beams, columns, and decking. These materials are often used as an alternative to traditional wood and steel, as they offer greater strength and durability, as well as lower maintenance requirements.

Pultruded materials are also commonly used in the transportation industry, particularly in the manufacture of buses and recreational vehicles. They are particularly well-suited to this application, as they offer high strength and durability at a relatively low weight, which helps to improve fuel efficiency and reduce emissions.

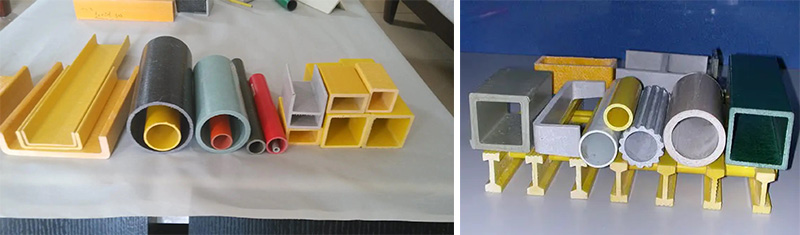

In the industrial equipment industry, pultruded materials are also widely used as an alternative to metal, as they are non-corrosive, rust-free, and highly durable. Pultruded grating and handrails are common in many industrial facilities, including chemical plants and oil refineries, as they are able to withstand harsh environments and heavy loads. Pultrusion can also be used to create various shapes and sections, such as angles, channels, I-beams, and T-sections.

Pultruded Profiles

Pultruded materials are also used in a range of other applications, including marine and offshore structures, electrical and telecommunications equipment, and consumer products. The process of pultrusion can produce a wide variety of shapes, sizes, and profiles, which makes it a versatile manufacturing process that can be used to produce a wide range of products.

In addition to its versatility, pultrusion has other advantages as well. The process is highly automated and repeatable, which makes it possible to produce large volumes of consistent, high-quality products. Pultrusion also has a relatively low energy consumption and low cost per pound of material produced, compared to other methods of producing composite materials. Pultrusion can also be done using a range of polymers and reinforcements, such as polyester, vinyl ester, epoxy, and polyurethane resins with fibers like glass, carbon, and aramid.

In conclusion, Pultrusion is a process of manufacturing composite materials that offer a high degree of strength and dimensional accuracy. It is used for a wide range of applications, including construction, transportation, and industrial equipment. Pultruded materials are strong, durable, and resistant to a wide range of environmental factors. Pultrusion is also a cost-effective process that can be easily automated, which allows for large volumes of consistent, high-quality products to be produced. With its versatility, low cost, and consistent properties, Pultrusion has been increasingly popular as an alternative to traditional materials in various industries.

info@unicomposite.com

info@unicomposite.com