Composite steel, glass fiber reinforced polymer (GFRP) reinforcement rebar is the solution to the corrosion of reinforced concrete structures. Glass fiber rebar is an ideal substitute for traditional types of rebar. Why?

Steel rebar limitations:

- Heavy (increase logistics costs and increase structural weight, thereby affecting the natural frequency of concrete structures)

- Corrosive (even stainless steel rust inhibitor, its price is 2 to 4 times higher than GFRP)

- Very high stiffness (structure becomes very rigid)

- Very limited fatigue resistance (cyclic load)

- High thermal conductivity

- Black steel, galvanized and epoxy coated steel bars are very expensive to maintain

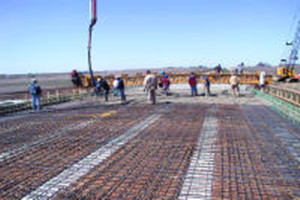

GFRP rebars, composite rebars, and glass fiber rebars are very suitable for applications where the performance of steel rebar is limited to its properties. In wet, coastal and cold countries, such as corrosion problems, GFRP rebar can be used to eliminate corrosion problems and all costs related to corrosion and maintenance.

If proper design and factors are to be considered, the initial cost of using GFRP rebar in the early stages of the project may not increase the project cost. The use of GFRP rebar can reduce project costs by up to 5%, and the structure does not require any major maintenance for the next 100 years.

GFRP rebar solves the limitations of steel rebar in the following ways:

- Light weight (4 times lighter)

- Higher rigidity than steel (allowing structural rigidity to decrease)

- Electrical and electrical isolation

- 100% corrosion resistance to alkali and acid environment

- 100 years of zero maintenance

info@unicomposite.com

info@unicomposite.com